If in a few years you happen to travel down Highway 85 in the Black Hills near Lead, South Dakota, you will find yourself passing beneath a new, narrow beam-like structure stretching across the road overhead.

You’ll be crossing under part of a conveyor system that will be used to transport rock from nearly a mile underground at the former Homestake gold mine — now the Sanford Underground Research Facility — to an enormous open pit on the surface as underground space is carved out to house a giant particle detector.

Scientists from the international Deep Underground Neutrino Experiment (DUNE), an experiment hosted by the U.S. Department of Energy’s Fermi National Accelerator Laboratory, will build and use the mammoth detector to study particles called neutrinos. Understanding these particles is expected to lead to a deeper knowledge of how our universe is put together.

The North Alabama Fabricating Company has been contracted to design and fabricate a rock conveyor to help remove rock from the former Homestake Mine. This effort is to make way for a giant particle detector for the international Deep Underground Neutrino Experiment. The detector will be situated nearly a mile underground. Image: Sanford Lab

On June 28, Fermi Research Alliance LLC, which operates Fermilab, signed a contract with North Alabama Fabricating Company to design and fabricate the pipe conveyor to be installed at Sanford Lab. The contract supports the excavation for the Long-Baseline Neutrino Facility (LBNF), the facility that will house and support DUNE.

“The fabrication and installation of the pipe conveyor will be a major step toward LBNF excavation,” said Mike Headley, executive director of the South Dakota Science and Technology Authority, or SDSTA, which owns and operates Sanford Lab. “It’s an exciting milestone, and the SDSTA is proud to support the LBNF team on this project.”

Fermilab and Sanford Lab staff expect conveyor installation to begin in mid-2018 and continue for six months. Rock removal is expected to take about three years once the conveyor begins operating.

The rock conveyor will transport rock excavated from the former Homestake Mine to a nearby open cut. Image: Sanford Lab

“The conveyor will transport about 800,000 tons of rock — approximately equal to the mass of eight Nimitz class aircraft carriers,” said retired U.S. Navy admiral Chris Mossey, who is now the LBNF project director at Fermilab.

Like a giant futuristic supermarket checkout lane, the rock conveyor will move rock over a stretch of 3,700 feet while containing dust and debris.

The conveyor path will take advantage of a long, existing tunnel carved out during Homestake’s gold mining days in the 1930s. The conveyor will start 175 feet underground, make its way to the surface, and continue high above ground until it arrives at the pit, called an open cut, which is roughly two miles wide and 1,200 feet deep. In fact, miners used a similar machine in the 1980s to transport rock away from the open cut as they looked for gold.

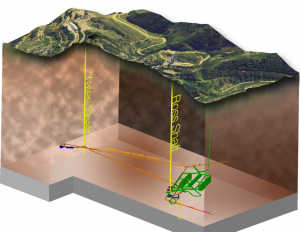

This is a conceptual illustration of the aboveground portion of the rock conveyor. Image: Sanford Lab

LBNF project members have kept in close contact with the city of Lead and its residents regarding rock-handling options, as well as with the State Historic Preservation Office to ensure that cultural aspects of the site are understood and respected. The communication will continue as the design evolves.

“The design team has worked hard to come up with the right system,” said Fermilab’s Elaine McCluskey, LBNF project manager.

Excavation for the DUNE detector caverns is expected to be complete in early 2022.

Editor’s note: The amount of rock to be excavated for LBNF at the South Dakota site mentioned in this article was updated on May 2, 2019.