Twenty-five years ago, there was a hole in the Standard Model. And on July 21, 2000, an experiment called DONUT filled it.

That’s when a team of 54 physicists from the United States, Japan, South Korea and Greece announced the first-ever detection of the tau neutrino, one of the last unseen particles in the Standard Model of particle physics. They were part of the Direct Observation of the Nu Tau, or DONUT, collaboration based at the U.S. Department of Energy’s Fermi National Accelerator Laboratory.

“We knew there was a tau neutrino — there had to be,” said Regina Rameika, a member of DONUT at the time and now associate director for high-energy physics at the Department of Energy. “But the fact is, we never had observed the signature of the interaction.”

Neutrinos are incredibly lightweight subatomic particles that were first postulated by Wolfgang Pauli in 1930. In 1956, physicists saw the first neutrino at the Savannah River Plant in South Carolina. They didn’t know about the neutrino’s different types, or flavors, at the time, but this first neutrino turned out to be an electron neutrino. In 1962, physicists at Brookhaven National Laboratory detected the second type, the muon neutrino.

The idea of a third flavor of neutrino materialized after an experiment led by physicist Martin Perl at SLAC National Laboratory found a particle called the tau in 1975. The tau is the third generation of particles known as leptons. Since the other two leptons — electrons and muons — had corresponding neutrinos, it made sense that there must also be neutrinos corresponding to the tau. Sure enough, experiments found indirect evidence for the tau neutrino’s existence.

But direct observational evidence remained scarce. Until DONUT.

Making DONUT

In the early 1990s, Fermilab physicists were gearing up for the Neutrinos at the Main Injector project, or NuMI, to search for neutrino mass. As the story goes, Fermilab scientists Rameika and Byron Lundberg were discussing how excited they were for NuMI and realized it would be very useful to directly observe the tau neutrino first. The idea for the DONUT experiment was born.

Lundberg and Rameika reunited a group of scientists who had worked on Fermilab’s Experiment 653 in the mid-1980s. E653 incorporated emulsion plates developed by physicists at Nagoya University in Japan to look for charm particles. DONUT would use similar technology to search for evidence of tau neutrinos.

The DONUT collaboration submitted their proposal in 1994 and were taking data by 1997.

“By today’s standards, it was actually relatively simple,” said Rameika. “Combined, it was difficult.”

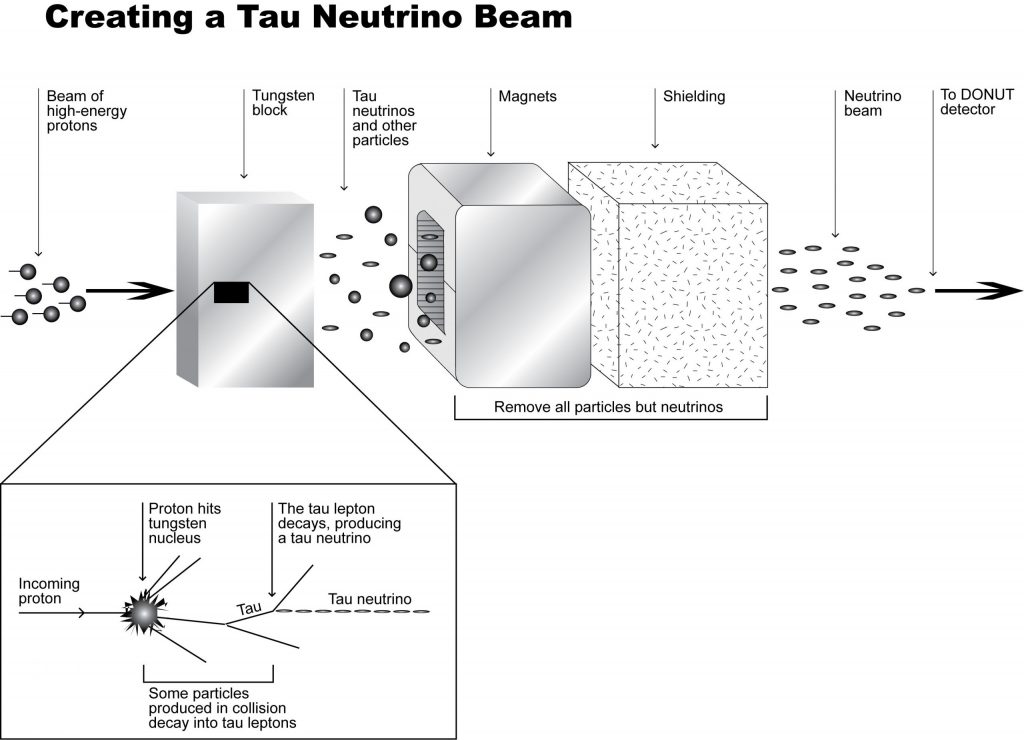

One challenge for DONUT was shoehorning it into the existing Fermilab program. The lab was uniquely equipped for this experiment because the Tevatron’s 800-GeV proton beam was essential for achieving the flux and energies they required to have even a chance of detecting tau neutrinos. But other experiments needed the beam, too. To make the effort as easy as possible for the lab, the collaboration repurposed existing equipment.

The experiment consisted of a 3-foot-long structure made of iron plates sandwiched with plates of emulsion. When Fermilab’s Tevatron accelerator shot a beam of particles at this target, the neutrinos interacted with the iron nuclei. The resulting particles shot through the emulsion plates, leaving tracks behind like animal footprints in the snow.

But if the experimenters weren’t careful, the emulsion plates could get polluted. The Tevatron beam produced an enormous amount of muons in addition to neutrinos, and these muons would overexpose the emulsion plates. Fortunately, since muons are charged particles, they can be steered with magnets, which don’t affect neutrinos.

Vittorio Paolone, who was co-spokesperson for DONUT with Lundberg at the time, compared the muon challenge to being between the jaws of a lion. “You have the jaws open, and then you have to stick the emulsion in between and hope it doesn’t clamp down at some point,” he said.

If the metaphorical jaws did clamp down, muons would flood the emulsion plates and DONUT would lose all their data. It would be akin to exposing a roll of film to the light before developing the photos. There were safeguards in place to protect the data: if the sweeping magnets failed, the beamline would automatically shut off. Fortunately for DONUT — and for every other Fermilab experiment using the beam at the same time — the magnet held steady.

With Fermilab’s high-energy proton beam, the nuclear emulsion technology pioneered by Nagoya University and the sweeping magnet system that shielded the detector, DONUT was the product of scientific serendipity. “The detection of tau-neutrino interactions using particle accelerators was only possible because three unique capabilities could be employed in a synergistic manner at the time DONUT was proposed,” said Lundberg.

After collecting data from 1997 to 1998, collaborators in Nagoya worked on digitizing and analyzing the emulsion plates. They then sent the data back to Fermilab for further analysis, which included early forms of machine learning and artificial intelligence. “We were one of the first experiments using neural networks,” said Rameika.

In total, DONUT collected 6.6 million particle interactions, which they narrowed down to about 1,000 candidate events.

If tau neutrinos acted as predicted, physicists expected to see their tell-tale signature in the emulsion plates: a short track with a kink in it, indicating a tau neutrino had hit an iron nucleus and produced a tau lepton, which traveled for about a millimeter before decaying.

“The signature is pretty obvious,” said Paolone, now a professor at the University of Pittsburgh. “Even though it looks exactly the way you expect it to look, when you start seeing three or four that look like a tau neutrino interaction … you start to get pretty excited.”

On July 21, 2000, Lundberg announced the detections of four tau neutrino interactions to a packed lecture hall at Fermilab. They had finally seen the penultimate piece of the Standard Model. (The observation of the final piece, the Higgs boson, would be announced 12 years later.) Ultimately, DONUT found a total of nine tau neutrino interactions.

“Personally, commissioning and running DONUT was challenging and exhausting,” said Lundberg. “I never worked as intensely after the experiment — I doubt that I even could have.”

The long legacy of a short interaction

The hard work of a small, international group of physicists had a profound impact on the field. In 2022, the American Physical Society recognized the achievements of DONUT by awarding the W.K.H. Panofsky Prize in Experimental Particle Physics to Lundberg, Rameika, Paolone and their Nagoya University collaborator Kimio Niwa “for the first direct observation of the tau neutrino through its charged-current interactions in an emulsion detector.”

The emulsion detection technology originated at DONUT has since been used in many more experiments, including ScanPyramids, an international project using noninvasive techniques to look for hidden chambers inside the pyramids in Egypt. CERN neutrino experiments like DsTau, FASERν and SND@LHC also utilize this tech. “The origin of the current nuclear emulsion technology is in the DONUT experiment,” said Mitsuhiro Nakamura, a DONUT collaborator from Nagoya University who recently retired from physics to become a rice farmer.

Nuclear emulsion plates were also used in the OPERA experiment at the Gran Sasso Laboratory of the Italian National Institute for Nuclear Physics. Between 2010 and 2015, OPERA saw 10 beam-produced muon neutrinos oscillate into tau neutrinos, making it one of two experiments that has detected tau neutrinos since their first observation. The other is the IceCube Neutrino Observatory, which announced seven tau neutrino candidates from cosmic sources in 2024 and a few more in following analyses. Collectively, physicists have seen, on average, one tau neutrino per year in the last quarter century.

“It’s impressive that we don’t have larger samples,” said Paolone. “It’s an amazingly difficult particle to detect.”

Many current and future experiments are focused on detecting — or have a chance of seeing — tau neutrinos. In addition to the CERN emulsion-based detectors that will look at energies similar to and higher than to DONUT, there are large-scale water- and ice-based detectors like KM3NeT, P-ONE and an expansion to IceCube that will probe high-energy neutrinos, and proposed tau-neutrino telescopes will explore ultra-high-energy ranges.

Physicists are also continuously brainstorming new ways to study tau neutrinos. “Ever since DONUT, we’ve had to learn how to find the tau neutrino signature without actually seeing the track,” said Rameika.

Some new-generation neutrino experiments, such as the Deep Underground Neutrino Experiment hosted by Fermilab, are focusing on the other two neutrino flavors that are relatively easier to detect.

Still, DONUT’s direct detection of the tau neutrino was a vital step in understanding the nature of the elusive particle.

“In order to understand neutrinos, you want to look at every channel that you possibly can,” said Rameika. “Knowing how to detect tau neutrinos, as we did with DONUT, is an important piece of information that we keep in the back of our heads for going forward and figuring out how to adapt it. In my mind, it was a critical historical experiment”

Fermi National Accelerator Laboratory is America’s premier national laboratory for particle physics and accelerator research. Fermi Forward Discovery Group manages Fermilab for the U.S. Department of Energy Office of Science. Visit Fermilab’s website at www.fnal.gov and follow us on social media.

John Peoples Jr., Fermilab director from 1989-1999, passed away on June 25, 2025 at the age of 92.

As the third director of Fermi National Accelerator Laboratory, his career spanned more than half of a century. Over the course of this time, Peoples led Fermilab during the run of the Tevatron, which contributed to the discovery of the top quark on March 2, 1995, made the Main Injector project a reality, and initiated an astrophysics program at Fermilab.

“Achieving great science requires great leadership, and John Peoples was that. His passion and dedication to physics and astrophysics led to significant contributions in Fermilab’s history,” said interim Fermilab Director, Young-Kee Kim. “He worked continually to maintain support from local, state and federal levels for Fermilab, helping secure funding for the Main Injector upgrade, which was significant to the lab’s rich science program since the 2000s,” she added.

Peoples earned his bachelor’s degree in electrical engineering from the Carnegie Institute of Technology in 1955. He worked briefly as an engineer before turning to physics, receiving his Ph.D. at Columbia University. Later in his career, that engineering background was often vital to finding solutions and solving technical problems.

He came to Fermilab on a sabbatical from Cornell in 1971 to start work on a photoproduction experiment. Joining the lab with temporary appointments as a scientist in 1972 and 1973, Fermilab’s first director, Robert Wilson, appointed him head of the proton beamline. Peoples officially joined the lab in April 1975 as head of the Research Division.

From 1980-1987, he led the design and construction of the antiproton source that collected and stored more antiprotons than any other facility in the world. In 1987, Peoples was appointed deputy director of Fermilab, and two years later he succeeded Leon Lederman as the lab director.

“John was tireless in his commitment to Fermilab and to it being the premier high energy physics laboratory in the U.S. He was ahead of his time in recognizing the talents and contributions of scientists at the lab who otherwise would’ve been overlooked,” said Regina Rameika, associate director for the Office of High Energy Physics in the Department of Energy’s Office of Science. During People’s tenure as director, Rameika led the MINOS and DONUT experiments at Fermilab and was the deputy head of the lab’s research division.

Credit: Reidar Hahn, Fermilab

Peoples formed an experimental astrophysics group in 1991 at Fermilab and the University of Chicago, and he was responsible for Fermilab becoming an early partner in what was to become the SDSS. Years later, he took on the role of director of the DES to pursue funding, collaboration from international partners and mentoring early career scientists.

In 2005, he worked with Fermilab to formally establish the Peoples Fellowship, created to assist young physicists interested in transitioning from experimental physics to accelerator physics. Over the last two decades, several dozen young researchers, many of whom achieved eminent positions in the scientific community, have benefited from the program.

Peoples was awarded the Robert R. Wilson Prize for Achievement in the Physics of Particle Accelerators from the American Physical Society in 2010 for his “critical and enduring efforts in making the Tevatron Collider the outstanding high-energy physics accelerator of the last two decades.”

In his retirement, Peoples made many visits back to Fermilab, checking on the status of projects like the Dark Energy Survey and talking to scientists about different experiments.

“John was a great leader,” said former Fermilab scientist Steve Holmes. “He was director during a very critical period, when the Tevatron accelerator really came to the forefront. And in the early ’90s he worked tirelessly to make the Main Injector project a reality. He realized that one day the Tevatron program would end, and the Main Injector would become the future of the lab. If not for this insight, Fermilab and the U.S. would not have an accelerator-based high-energy physics program today.”

Fermi National Accelerator Laboratory is America’s premier national laboratory for particle physics and accelerator research. Fermi Forward Discovery Group manages Fermilab for the U.S. Department of Energy Office of Science. Visit Fermilab’s website at www.fnal.gov and follow us on social media.

Forty high school students with Chicago Public Schools graduated from Fermi National Accelerator Laboratory’s Saturday Morning Quantum* (SMQ*) program on May 31, 2025.

The inaugural 10-week program was held at the Olive Harvey College Learning Center in Chicago’s South Shore community, near the Midwest’s up and coming global destination for quantum, the Illinois Quantum Microelectronics Park — a planned 128-acre quantum computing technology campus.

“Teaching students about how the world works at the quantum level and how quantum technology could transform our life is imperative in this rapidly changing world,” said Young-Kee Kim, interim director of Fermilab.

This new program was modeled after Fermilab’s Saturday Morning Physics (SMP) outreach program that is held annually at the laboratory in Batavia, Illinois. SMP has been successfully running for over 40 years.

SMQ* — the asterisk meaning “more” — was developed by Fermilab’s Education and Public Engagement team along with the lab’s Superconducting Quantum Materials Systems team to bring a quantum science curriculum to high school students in the City of Chicago.

Once a week during the 10-week course students learned about core topics in the field of quantum science and quantum computing — including quantum mechanics, superconducting technology, quantum computing and sensing, engineering and cryogenic platforms for quantum computers.

On top of gaining technical and scientific knowledge, students worked with quantum scientists and engineers and learn about what led them to pursue their career paths.

Commenting on the experience, one student said, “Thanks to the teachers, I was able to learn more about quantum and quantum computing. There were no dumb questions in class.”

Led by Fermilab staff, students also had the opportunity to tour laboratories and scientific spaces at Fermilab, including the Superconducting Quantum Materials and Systems Center (SQMS), where scientists and researchers work to develop and deploy the world’s most powerful quantum computers and sensors.

“Touring Fermilab and learning what they do and how they do it was rewarding,” said another student.

During the graduation ceremony, students received certificates for completing the program.

With programs like SMQ*, Fermilab is building pathways into science for Chicagoland students by bringing hands-on learning and mentorship into the heart of Chicago while inspiring future generations of scientists.

The Superconducting Quantum Materials and Systems Center is one of the five U.S. Department of Energy National Quantum Information Science Research Centers. Led by Fermi National Accelerator Laboratory, SQMS is a collaboration of 36 partner institutions — national labs, academia and industry — working together to bring transformational advances in the field of quantum information science. The center leverages Fermilab’s expertise in building complex particle accelerators to engineer multiqubit quantum processor platforms based on state-of-the-art qubits and superconducting technologies. Working hand in hand with embedded industry partners, SQMS will build a quantum computer and new quantum sensors at Fermilab, which will open unprecedented computational opportunities. For more information, please visit sqmscenter.fnal.gov.

Fermi National Accelerator Laboratory is America’s premier national laboratory for particle physics and accelerator research. Fermi Forward Discovery Group manages Fermilab for the U.S. Department of Energy Office of Science. Visit Fermilab’s website at www.fnal.gov and follow us on social media