Lead, S.D. (Aug. 15, 2024) — A ribbon-cutting event was held today at the Sanford Underground Research Facility (SURF) in Lead, S.D. to mark the completion of excavation work for the Long-Baseline Neutrino Facility/Deep Underground Neutrino Experiment (LBNF/DUNE), an international project led by the U.S. Department of Energy’s Fermi National Accelerator Laboratory. The “Into the Depths of Discovery” event, hosted by Fermilab and the South Dakota Science and Technology Authority (SDSTA), was attended by supporters of the three-year excavation of the caverns, including state and federal leaders as well as Department of Energy officials.

Fermilab Director Lia Merminga (center, left) and Sanford Underground Research Facility Director Mike Headley (center, right) cut the ribbon to mark the completion of the three-year excavation of the caverns for the Long-Baseline Neutrino Facility/Deep Underground Neutrino Experiment. Supporters and people instrumental in the project helping to hold the ribbon are (left to right): LBNF/DUNE-US Federal Project Director Adam Bihary, CERN Senior Scientist and Neutrino Platform Project Leader Francesco Lanni, DUNE Collaboration Co-spokesperson Sergio Bertolucci, President and CEO of Universities Research Association John Mester, Department of Energy Assoc. Director for the Office of High Energy Physics Gina Rameika, DOE Principal Deputy Under Secretary for Science and Innovation Derek Passarelli, DOE Chief of Staff of Secretary Jennifer Granholm Christopher Davis, Acting DOE Director of the Office of Science and Deputy Director for Science Programs Harriet Kung, South Dakota Lt. Gov. Larry Rhoden, U.S. Senator for S.D. Mike Rounds, U.S. Rep. for S.D. Dusty Johnson, University of Campinas Rector Antonio José de Almedia Meirelles, LBNF/DUNE-US Project Director Jim Kerby. Credit: Ryan Postel, Fermilab

“Today we celebrate this remarkable engineering feat and are grateful to the many people who worked to achieve this milestone,” said Derek Passarelli, DOE Principal Deputy Under Secretary for Science & Innovation. “This is an extraordinary achievement given the nature of the underground excavation. The LBNF/DUNE endeavor, involving partners from the nation as well as from around the world, will bring together our collective minds and talents focused on tackling the most challenging questions about how our universe works.”

The event occurred one mile beneath the surface at the northern detector cavern and marked the completion of excavation work on two seven-story caverns for housing particle detectors (see 2-minute animation), as well as a smaller central utility cavern. The two detectors will each be filled with 17,000 tons of liquid argon cooled to minus 184 degrees Celsius to record and study the rare interactions of neutrinos.

A mile underground, Fermilab Director Lia Merminga (left) discusses the progress of the three caverns for the Long Baseline Neutrino Facility/Deep Underground Neutrino Experiment with Construction Coordinator Nathan Strasbaugh (right) on Thursday, August 15, 2024 in Lead, S.D. Credit: Ryan Postel, Fermilab

The international collaboration of DUNE scientists will study the behavior of mysterious particles known as neutrinos to address some of the biggest questions in science, such as why our universe contains matter, how an exploding star can create a black hole, and if neutrinos are connected to dark matter or other undiscovered particles.

“It is exciting to have so many people here today who have supported the excavation and construction of the project,” said Lia Merminga, director of Fermilab. “This is an important step in making LBNF/DUNE a world-class international underground science facility.”

The research conducted at Fermilab and SURF is the foundation for future technological innovation. The history of scientific research shows that discoveries made today have the potential to positively impact humanity for generations to come.

Two colossal caverns, each more than 500 feet long and seven-stories tall, were completed to contain the gigantic particle detector modules for the Long-Baseline Neutrino Facility/Deep Underground Neutrino Experiment, an international collaboration led by Fermilab. A third cavern will house utilities for the operation of the DUNE far detector. Credit: Ryan Postel, Fermilab

“This important milestone is a great way to celebrate the world-class research, innovation, education, and economic opportunities happening here at America’s Underground Lab,” said Mike Headley, laboratory director at SURF and the executive director of the South Dakota Science and Technology Authority. “The research underway at SURF will extend well into this century; the impact of scientific advancements made here could last much longer. Our future is incredibly bright, and we are excited to help it unfold.”

Engineering, construction and excavation teams have worked 4,850 feet below the surface since 2021 at SURF to prepare the space needed for the experiment. Over 800,000 tons of rock were excavated and moved from underground to an expansive former surface mining area known as the Open Cut. In order to accomplish this feat, construction crews dismantled heavy mining equipment and, piece by piece, transported it underground. Workers then reassembled the machinery and have been blasting and relocating rock ever since.

The U.S. Department of Energy’s Fermi National Accelerator Laboratory and Sanford Underground Research Facility are working together for this international science project as part of a large collaboration comprised of more than 1,400 scientists and engineers from over 200 institutions in over 35 countries and the European Organization for Nuclear Research, known as CERN.

View the full recording of the event here

About Fermilab and DOE Office of Science:

Fermilab is America’s premier national laboratory for particle physics and accelerator research. A U.S. Department of Energy Office of Science laboratory, Fermilab is located near Chicago, Illinois, and operated under contract by the Fermi Research Alliance LLC. Visit Fermilab’s website at www.fnal.gov and follow us on X/Twitter at @Fermilab.

The DOE Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, please visit science.energy.gov.

About SURF:

Sanford Underground Research Facility is operated by the South Dakota Science and Technology Authority (SDSTA) with funding from the Department of Energy’s Office of Science. We are America’s Underground Lab. Our mission is to advance world class science and inspire learning across generations. Visit SURF at www.sanfordlab.org.

In a major step for the international Deep Underground Neutrino Experiment, scientists have detected the first neutrinos using a DUNE prototype particle detector at the U.S. Department of Energy’s Fermi National Accelerator Laboratory.

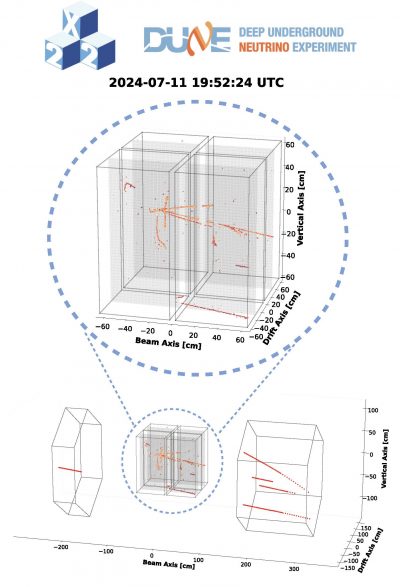

Display of a candidate neutrino interaction recorded by the 2×2 detector highlighting the four internal detector modules and native 3D imaging capability. The bottom image additionally shows the detectors surrounding the 2×2 for further tracking of incoming and exiting particles. The DUNE Near Detector will similarly consist of a modular liquid argon detector along with a muon tracker. Credit: DUNE Collaboration

DUNE, currently under construction, will be the most comprehensive neutrino experiment in the world. It will bring scientists closer to solving some of the biggest physics mysteries in the universe, including searching for the origin of matter and learning more about supernovae and black hole formation.

Since DUNE will feature new designs and technology, scientists are testing prototype equipment and components in preparation for the final detector installation. In February, the DUNE team finished the installation of their latest prototype detector in the path of an existing neutrino beamline at Fermilab. On July 10, the team announced that they successfully recorded their first accelerator-produced neutrinos in the prototype detector, a step toward validating the design.

“This is a truly momentous milestone demonstrating the potential of this technology,” said Louise Suter, a Fermilab scientist who coordinated the module installation. “It is fantastic to see this validation of the hard work put into designing, building and installing the detector.”

The new neutrino detection system is part of the plan for DUNE’s near detector complex that will be built on the Fermilab site. Its prototype — known as the 2×2 prototype because it has four modules arranged in a square — records particle tracks with liquid argon time projection chambers. The final version of the DUNE near detector will feature 35 liquid argon modules, each larger than those in the prototype. The modules will help navigate the enormous flux of neutrinos expected at the near site.

The 2×2 prototype implements novel technologies that enable a new regime of detailed, cutting-edge neutrino imaging to handle the unique conditions in DUNE. It has a millimeter-sized pixel readout system, developed by a team at DOE’s Lawrence Berkeley National Laboratory, that allows for high-precision 3D imaging on a large scale. This, coupled with its modular design, sets the prototype apart from previous neutrino detectors like ICARUS and MicroBooNE.

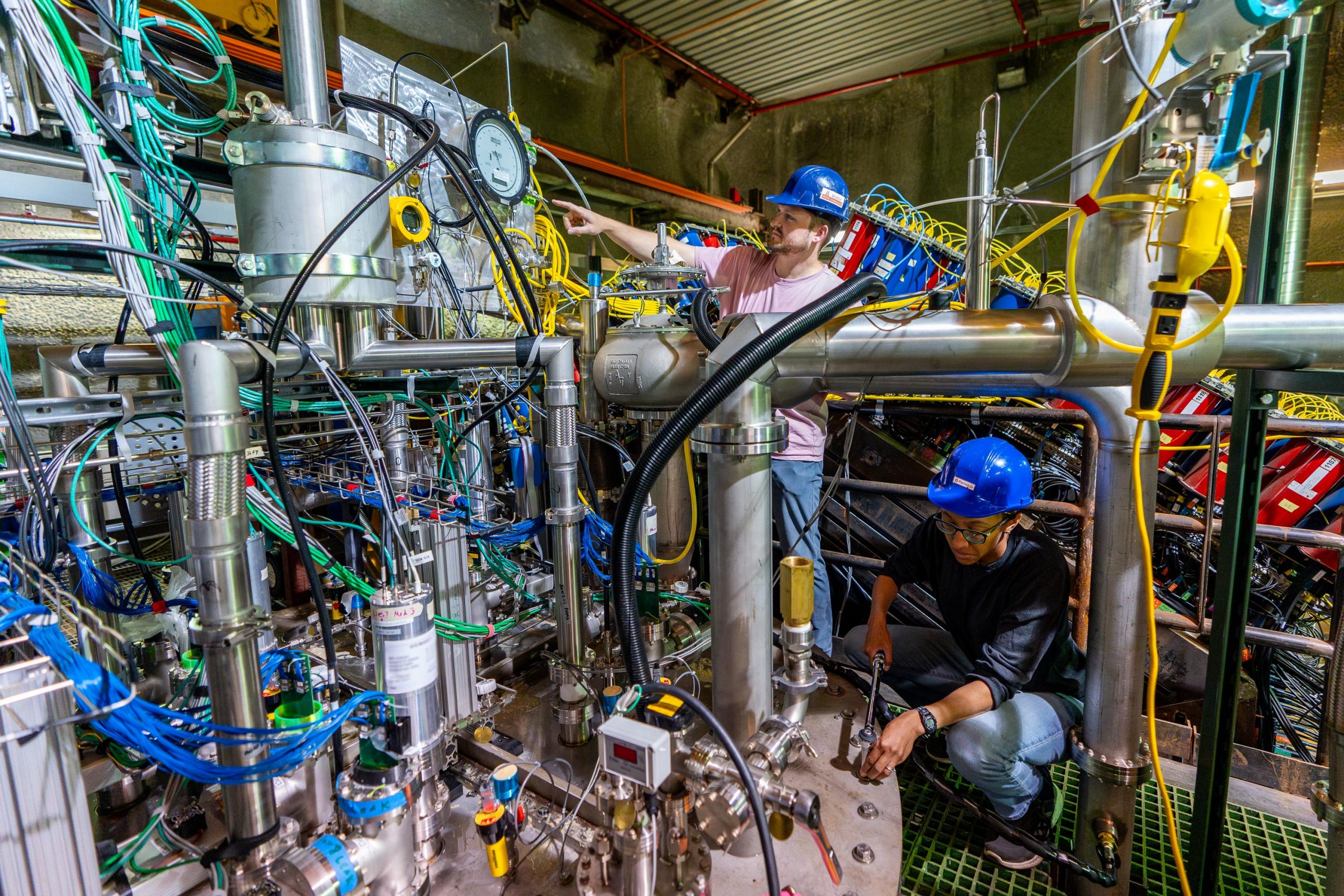

The 2×2 prototype detector for the DUNE near detector was placed in its cryostat in October 2023. Pictured are Kevin Wood, a Chamberlain Postdoctoral Fellow at Berkeley Lab and run coordinator for the 2×2 prototype; and Brooke Russell, now the Neil and Jane Pappalardo Special Fellow in Physics at MIT and the 2×2 prototype’s charge readout expert. Photo Credit: Dan Svoboda, Fermilab

Now, the 2×2 prototype provides the first accelerator-neutrino data to be analyzed by the DUNE collaboration.

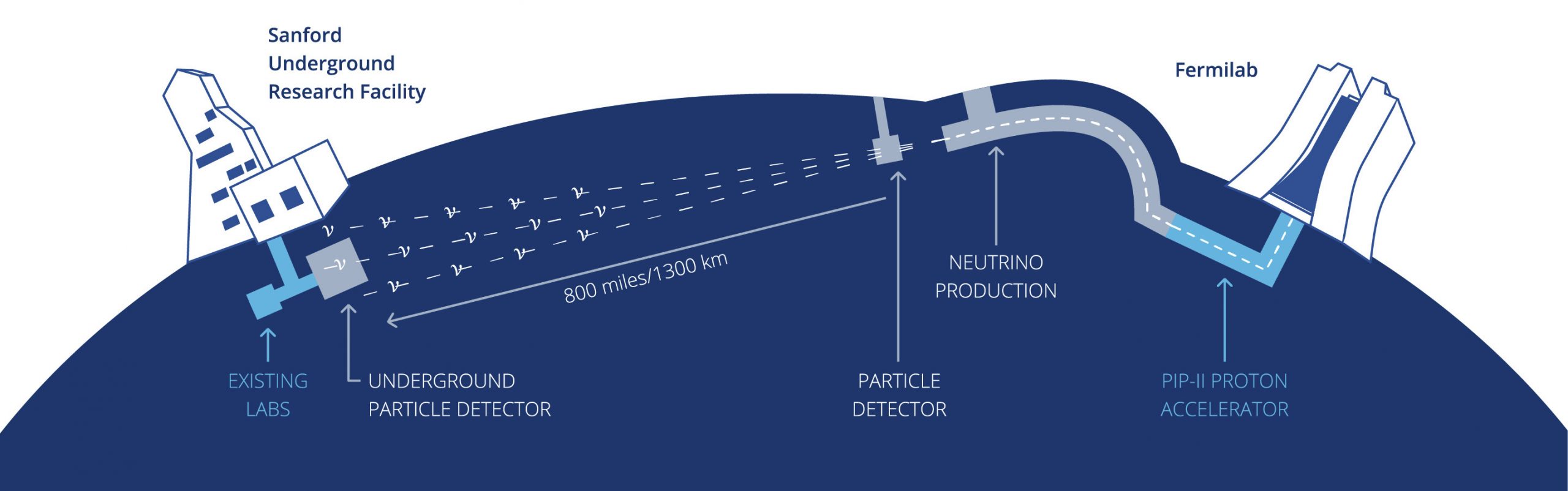

DUNE is split between two locations hundreds of miles apart: a beam of neutrinos originating at Fermilab, close to Chicago, will pass through a particle detector located on the Fermilab site, then travel 800 miles through the ground to huge detectors at the Sanford Underground Research Facility in South Dakota.

The DUNE detector at Fermilab will analyze the neutrino beam close to its origin, where the beam is extremely intense. Collaborators expect this near detector to record about 50 interactions per pulse, which will come every second, amounting to hundreds of millions of neutrino detections over DUNE’s many expected years of operation. Scientists will also use DUNE to study neutrinos’ antimatter counterpart, antineutrinos.

DUNE scientists will send a beam of neutrinos from Fermilab to huge detectors in South Dakota — a journey of about 800 miles. Image: Fermilab

This unprecedented flux of accelerator-made neutrinos and antineutrinos will enable DUNE’s ambitious science goals: Physicists will study the particles with DUNE’s near and far detectors to learn more about how they change type as they travel, a phenomenon known as neutrino oscillation. By looking for differences between neutrino oscillations and antineutrino oscillations, physicists will seek evidence for a broken symmetry known as CP violation to determine whether neutrinos might be responsible for the prevalence of matter — and hence everything — in our universe.

A team of 2×2 scientists at the Fermilab detector operations center monitoring the start-up of the detector. Credit: Dan Svoboda

The DUNE collaboration is made up of more than 1,400 scientists and engineers from over 200 research institutions. Nearly 40 of these institutions work on the near detector. Specifically, hardware development of the 2×2 prototype was led by the University of Bern in Switzerland, DOE’s Fermilab, Berkeley Lab and SLAC National Accelerator Laboratory, with significant contributions from many universities.

“It is wonderful to see the success of the technology we developed to measure neutrinos in such a high-intensity beam,” said Michele Weber, a professor at the University of Bern — where the concept of the modular design was born and where the four modules were assembled and tested — who leads the effort behind the new particle detection system. “A successful demonstration of this technology’s ability to record multiple neutrino interactions simultaneously will pave the way for the construction of the DUNE liquid argon near detector.”

Next steps

Testing the 2×2 prototype is necessary to demonstrate that the innovative design and technology are effective on a large scale to meet the near detector’s requirements. A modular liquid-argon detector capable of detecting high rates of neutrinos and antineutrinos has never been built or tested before.

The existing Fermilab beamline is an ideal place for testing and presents an exciting opportunity for the researchers to measure these mysterious particles. It is currently running in “antineutrino mode,” so DUNE scientists will use the 2×2 prototype to study the interactions between antineutrinos and argon.

Michele Weber, a professor at the University of Bern in Switzerland, spearheaded the 2×2 prototype efforts. Image: Dan Svoboda, Fermilab

When antineutrinos hit argon atoms, as they will in the argon-filled near detector, they interact and produce other particles. The prototype will observe what kinds of particles are produced and how often. Studying these antineutrino interactions will prepare scientists to compare neutrino and antineutrino oscillations with DUNE.“Analyzing this data is a great opportunity for our early-career scientists to gain experience,” said Kevin Wood, the first run coordinator for the 2×2 prototype and a postdoctoral researcher at Berkeley Lab, where the prototype’s novel readout system was developed. “The neutrino interactions imaged by the 2×2 prototype will provide a highly anticipated dataset for our graduate students, postdocs and other young collaborators to analyze as we continue to prepare to bring DUNE online.”The DUNE collaboration plans to bombard the 2×2 prototype with antineutrinos from the Fermilab beam for several months.

Sergio Bertolucci, professor of physics at the University of Bologna in Italy and co-spokesperson of DUNE with Mary Bishai of Brookhaven National Laboratory, said, “This is an exciting milestone for the 2×2 team and the entire DUNE collaboration. Let this be the first of many neutrino interactions for DUNE!”

Fermi National Accelerator Laboratory is supported by the Office of Science of the U.S. Department of Energy. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, please visit science.energy.gov.

Pantaleo Raimondi has long been fascinated by how things work.

“I like to understand everything. I don’t want to leave anything unexplored,” Raimondi said. “Even in a car, I try to understand exactly all the pieces that are there, why they work, and so on.”

It made some sense, then, that Raimondi opted to pursue a career in physics. “Physics really gives you a lot of answers,” he added.

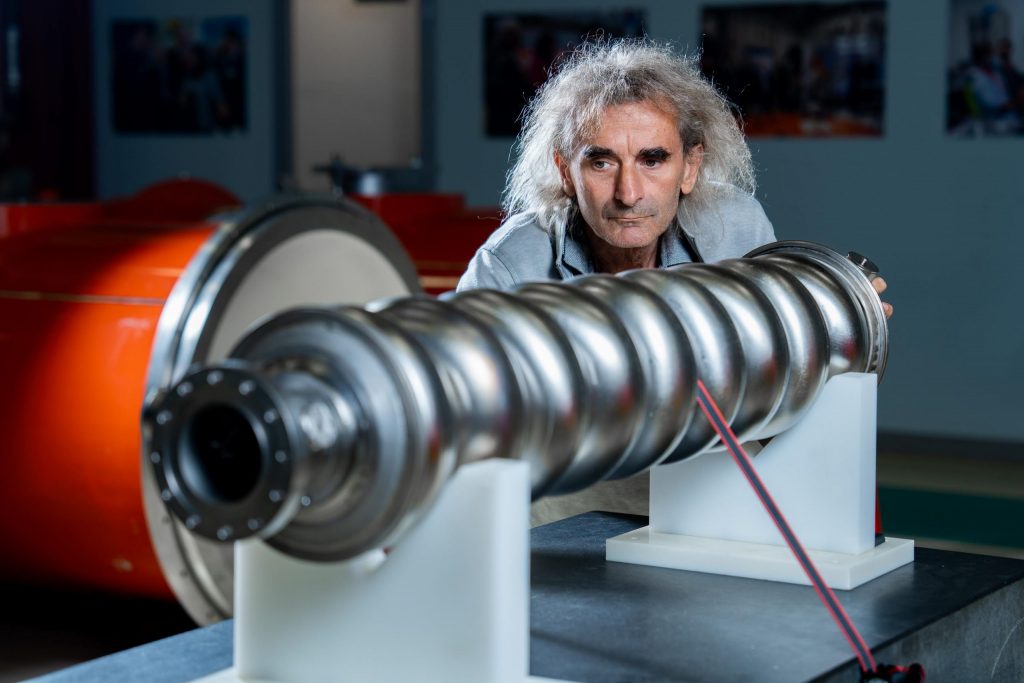

Physicist Pantaleo Raimondi is the new project director for the PIP-II collaboration that is upgrading the accelerator complex at Fermilab. Photo: Dan Svoboda, Fermilab

But when he decided to come to Fermilab, America’s premier particle and accelerator physics laboratory, Raimondi said it was for the people.

“I have a good experience working in teams,” said the Italian accelerator physicist. “Since I have joined many, many teams in my life, I know how teams are, at a glance. And here at Fermilab, when I came, I realized that the team here is really beautiful.”

Raimondi is the new project director for the Proton Improvement Plan II. The PIP-II collaboration is upgrading the accelerator complex at the U.S. Department of Energy’s Fermi National Accelerator Laboratory, just outside of Chicago. To do this, a new superconducting linear accelerator is being constructed that will eventually send neutrinos to the Deep Underground Neutrino Experiment, enabling the advancement of neutrino physics for decades to come.

“Throughout my life, I’ve always been attracted by new experiments, new challenges, new projects,” he said. “I prefer to stay in one place, but then something else shows up and, somehow, I get attracted. This is true as well for PIP-II.”

“Leading PIP-II is a very challenging endeavor,” said Cristian Boffo, PIP-II project manager. “The technology that is being developed for the machine is beyond state of the art. Over 300 people from all Fermilab directorates work on PIP-II every day, and international partners from five countries provide significant in-kind components and share invaluable knowhow.”

“But in the few months since he joined Fermilab, Pantaleo has fully integrated into the team,” Boffo added. “He has begun providing precious guidance in key areas of the project and has set the pace for the years to come.”

“Throughout my life, I’ve always been attracted by new experiments, new challenges, new projects.” Photo: Dan Svoboda, Fermilab

The path to Fermilab

Raimondi did his graduate studies as part of the ALEPH particle detector collaboration at CERN in Switzerland. After earning his Ph.D., Raimondi went back and forth between a research center for the Italian National Agency for New Technologies, Energy and Sustainable Economic Development in Frascati, Italy, and SLAC National Accelerator Laboratory in Menlo Park, California.

Throughout this earlier part of his career, he worked on the design and development of radiofrequency power systems, theoretical and technical analyses of linear accelerators and microtrons, beam transport studies and other topics related to electron accelerators, beam-based alignment and final-focus systems.

Later, Raimondi was appointed head of the accelerator division at Italy’s National Institute for Nuclear Physics National Laboratory of Frascati in Rome. There, he participated in commissioning DAFNE, an electron-positron collider. Raimondi contributed to improving the understanding and performance of DAFNE and developed new techniques to improve its luminosity.

Most recently, Raimondi was based in Grenoble, France, at the European Synchrotron Radiation Facility. There, he led the upgrade of the ESRF synchrotron ring, building the brightest synchrotron source in the world — 100 times more powerful than its predecessor. His revolutionary design of the synchrotron’s “extremely brilliant source” is now being replicated by all major synchrotron light sources around the world, including Raimondi’s new neighbors at Argonne National Laboratory. Raimondi even spent time in Switzerland to discuss his lessons learned with CERN scientists to inform the development of their Future Circular Collider.

In January, Raimondi moved to the Chicago area and officially joined Fermilab. He was preceded by Rich Stanek, who had served as the interim director of PIP-II since April 2022.

Raimondi’s first taste of a Chicago winter didn’t faze him; he said that he likes the snow and the cold. In general, Raimondi enjoys spending time in nature and likes sports “of any kind.” So far, he said he’s done a lot of bicycling and running.

But some of his favorite activities cultivated in the French Alps, on the Italian coast and in California’s Bay Area are harder to do in Batavia — for example, paragliding, mountain climbing, surfing and wind surfing. “But,” he joked, “it’s good, because then I will focus more on working.”

Steering the boat

With his expertise in running projects in many different phases, Raimondi said he was comfortable jumping into a project that’s already moving along. “When I joined the project, it was in a very advanced state, and it’s doing very, very well,” he said.

In his first few months on the job, Raimondi said he’s trying to absorb a fire hose of new information. “I’m getting acquainted and trying to not do many stupid things,” he said.

“You can say that the project is like a big, huge boat. … At this stage, what is really important is removing the rocks, the obstacles from the path of the boat,” he said.

As one of Fermilab’s flagship projects, PIP-II has a never-ending stream of tasks for Raimondi to keep an eye on. The PIP-II site at Fermilab is under construction, new technology is being developed and components of the accelerator are being assembled and tested. For example, the team is assessing a prototype cryomodule after it was shipped to the United Kingdom and back to validate its transportation system; at the same time, they are preparing to assemble another unit in the newly qualified clean room at Fermilab.

“Pantaleo joined PIP-II at the right time,” said Allan Rowe, PIP-II technical integration manager. “As the project wraps up all final design activities, pushes through the procurement phase and begins detailed integration and commissioning planning, his experience from leading these efforts at ESRF and elsewhere will be invaluable.”

Raimondi thinks PIP-II is already “pretty solid.” As with any large project, there will be “ordinary challenges” related to executing the project on time and on budget. However, Raimondi assures that he and his team will get the new linear accelerator — and the physics results — done, no matter what.

As for the people, Raimondi is still impressed by the PIP-II team.

“Knowing more and more about my colleagues is a confirmation of my first impression,” he said. “I’m really looking forward to continuing.”

Fermi National Accelerator Laboratory is supported by the Office of Science of the U.S. Department of Energy. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, please visit science.energy.gov.