A miniaturized technology originally developed for the Compact Muon Solenoid (CMS) experiment at the Large Hadron Collider in Geneva now is available for applications in maritime safety and homeland security.

This technology — silicon strip cosmic-muon detectors — has earned an R&D 100 Award for a team of scientists from the U.S. Department of Energy’s Fermi National Accelerator Laboratory — its 14th since 1980 — and its partners in the project, the Nevada National Security Site (NNSS) and the DOE’s Los Alamos National Laboratory.

The award-winning detectors were modified from silicon detector technology that high-energy physicists have used for years.

“It’s like a natural X-ray machine,” said Fermilab scientist Ron Lipton, who led the team that designed, mounted, assembled and tested the sensors. “It’s a synergistic use of what we’ve been doing already. We were able to use some of the engineering expertise here at the site to build these detectors.”

R&D 100 awards are presented annually by R&D Magazine in recognition of exceptional new products or processes that were developed during the previous year. An independent panel of judges selects the awardees based on the technical significance, uniqueness, and usefulness of projects and technology from across industry, government, and academia.

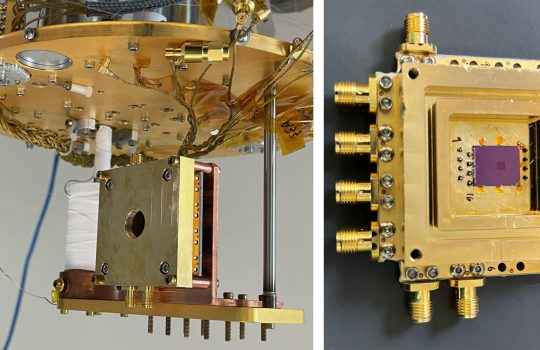

Silicon strip detectors like these are thin and lightweight, allowing them to be portable and easily embedded in structures. Photo: Mission Support and Test Services LLC

Cosmic-ray muons rain continuously upon Earth, produced when charged particles from deep space strike the upper atmosphere. Approximately 10,000 muons per minute per square meter arrive at sea level. This shower of subatomic particles passes unnoticed through all kinds of objects. Unlike X-rays, they even can traverse steel and other solid materials. And when captured by detectors placed behind or underneath an object, these muons can reveal what is inside.

Muons have been used to produce tomographic images of the interior of pyramids in Egypt and of nuclear reactors at Japan’s Fukushima Daiichi plant, which was heavily damaged by earthquakes and an ensuing tsunami in 2011. Radiation detectors and X-ray scanners are unable to penetrate materials concealed in concrete, lead and other materials, but muons can.

The technology may lend itself to additional applications that call for remote viewing of hazardous materials, Lipton said. These include verifying how much material is contained in concrete fuel casks, for example.

Leading the muon detector project was J. Andrew Green, principal scientist for the NNSS’ Remote Sensing Laboratory at Nellis Air Force Base in Nevada. Green had conducted research at Fermilab’s DZero experiment from 1997 to 2001 as a doctoral student at Iowa State University. During that period, Green met Lipton, Mike Utes, Cristian Gingu, Johnny B. Green and Paul Rubinov, who, along with William Cooper, composed the award-winning project team.

Andrew Green had worked with Utes and John Green on a key component of an upgrade to the DZero detector.

“From that experience, I knew who to call when I had my idea to build a silicon-based tracking system,” said Andrew Green, who later also worked as a postdoctoral scientist on the MiniBooNE neutrino experiment at Fermilab.

Green wrote the analysis software for reading the muon detector system’s data files, performing diagnostics and plotting muon signals in the detector in three dimensions.

“Even projects of this small scale require good software development to properly organize the large number of channels, data types and associated geometry,” he explained.

Fermilab’s cosmic-muon detector work is an outgrowth of its experience in building many tens of square yards of silicon sensors for the CMS experiment. The sensors the team developed for homeland security applications cover only a few square feet and are built in four planes that come in packages two inches thick.

Drift-tube detectors are currently used for position-sensitive particle detection in homeland security applications. Their thickness and weight cause problems for storage, shipment and deployment. Lightweight silicon strip detectors, meanwhile, are easily handled by humans or robots, and their precision dramatically reduces tracking and calibration software requirements. Image: Mission Support and Test Services LLC

They could potentially replace the bulky drift tube detectors in current use, which are two feet thick. The latter’s size and weight make them more difficult to ship and deploy. Their larger bulk is needed to boost the lower resolution of the muons passing through them as compared to the silicon strip technology, which can be used in thin layers. The conventional drift tube technology also presents potential hazards because it depends upon sets of cylindrical tubes that are filled with flammable gas and charged to high voltage to boost the signal.

Lipton, who specializes in silicon tracker detectors, led the construction of several silicon-based muon detectors for the DZero experiment, which finished data collection in 2011. He and his associates now are building a large-area silicon system for the Large Hadron Collider, which uses stacked planes of similar detectors in a somewhat different geometry.

“These are hundreds of square meters of material,” Lipton said. “They’re unprecedented in scale.”

Funding for silicon strip muon detectors for homeland security was provided by the National Nuclear Security Administration’s Laboratory-Directed Research and Development and Site-Directed Research and Development programs.