How long have you been working at Fermilab?

It’ll be 40 years in December. I like working here. I’ve gotten to do a little bit of everything through the years.

What do you do at the lab?

I’m a tech specialist, which is essentially a mechanic. Currently I’m testing and modifying radio-frequency superconducting cavities made of niobium that go into particle accelerators. My co-worker and I hang the cavities and get them ready for testing in large dewars. Once they’re cooled to cryogenic temperatures, the cavities are used to increase the energy of the beams of charged particles in an accelerator. They come in all different scales — from the size of your fingernail to six feet long — and they’re used for all kinds of different experiments.

I work with a large rock tumbler, essentially, to polish the interior of the cavities. If there’s a pit or defect inside a cavity even the diameter of your hair, it can interfere with the superconducting properties of the niobium.

What’s been your favorite project to work on?

Almost any project I work on is a favorite because I enjoy working with my hands. I started as a carpenter, but I’ve done so many projects over the years. The area I enjoyed the most was the Materials Development Lab, or MDL, where I got to work with a bunch of different materials and tools — from applying epoxies to woodworking.

You’re known around the lab for your woodworking. What kind of pieces do you make?

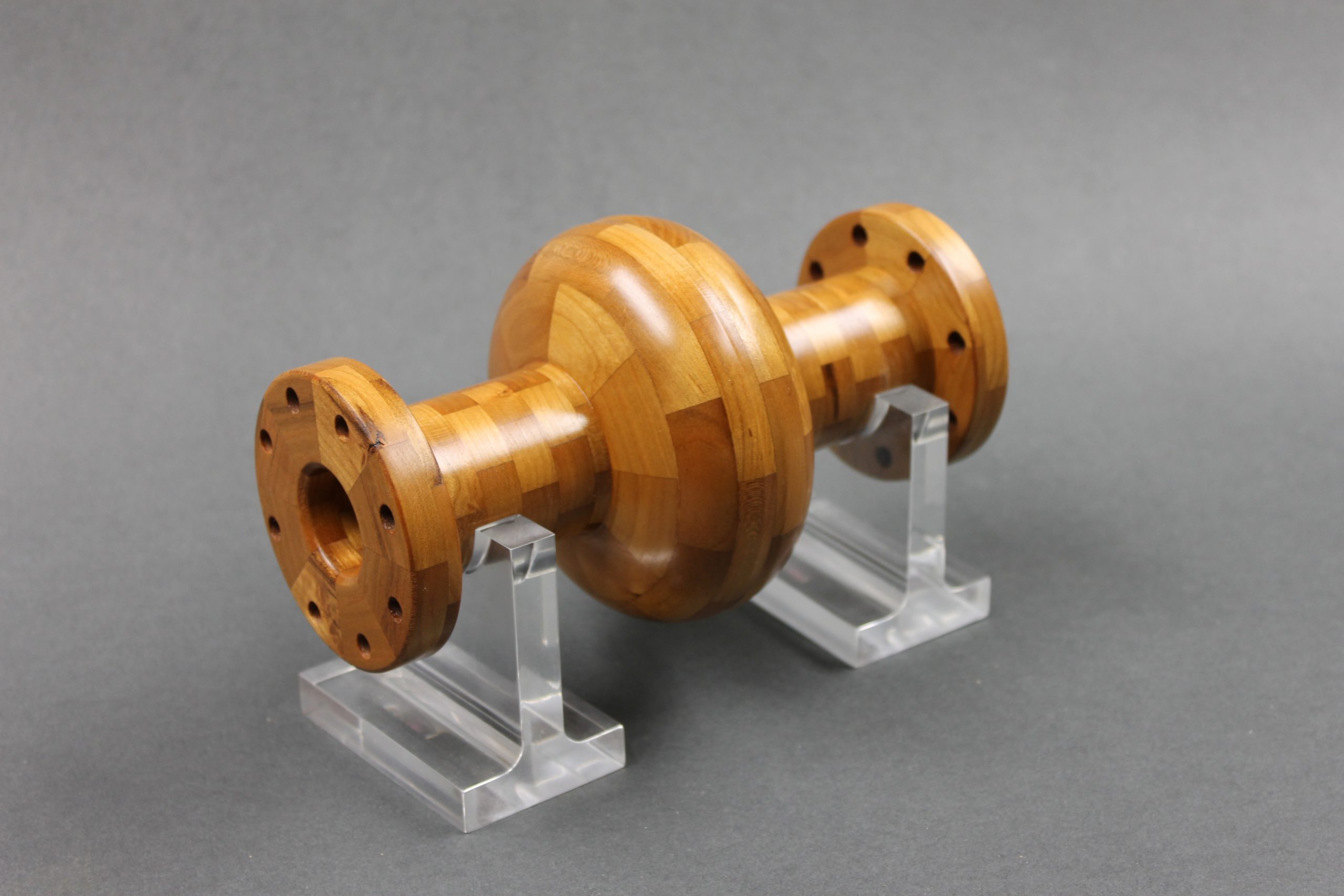

Everything from fountain pens to children’s toys to displays on the 15th floor of Wilson Hall. When I was in the MDL, I had to make these clear acrylic models of superconducting cavities for an engineering project. I thought to myself, “Why not just make a wooden one?” I started making wooden models of items at Fermilab in my shop at home, like the Tractricious sculpture and most recently a full-sized stylized replica of a niobium cavity. The cavity model is made of 128 segmented pieces of cherry, and it took around 20 hours to cut, glue, turn, sand and finish it.

I grew up on a farm, and we didn’t have a whole lot of money. My mom and dad would always refinish furniture for our house. I have some of their refinished antiques in my home now, and that’s how I got started in woodworking. I’ve been doing it ever since. I really owe it to my mom and dad.

What do you do with the wooden models when they’re finished?

I make stuff to give away. I don’t like the expectations that come with selling pieces. It puts pressure on me. I like to make stuff just for the journey.

How has your woodworking hobby affected your job?

I belong to a couple local woodworking clubs. I’m the photographer for the Windy City Woodturners and vice president of the Fox Valley Woodworkers Club. I’ve also been taking classes at the Marc Adams School of Woodworking in Indianapolis. My clubs keep me up on safety issues and allow me to practice working with wood and other materials. The more projects I take on, the safer and more efficient my work becomes.

Fermilab accelerator R&D is supported by the DOE Office of Science.

Fermilab is supported by the Office of Science of the U.S. Department of Energy. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, visit science.energy.gov.