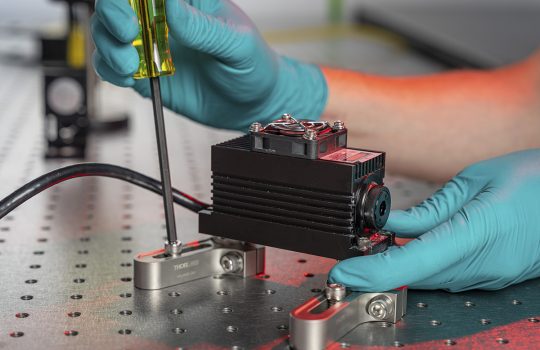

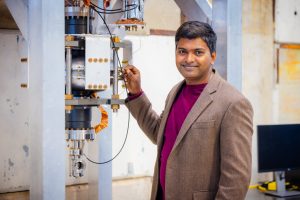

Particle accelerators have many uses in industrial settings. To advance a new type of compact particle accelerator, the U.S. Department of Energy has awarded funding to Charles Thangaraj, a senior scientist at the DOE’s Fermi National Accelerator Laboratory. He and his colleagues are developing devices called cathodes that will generate electrons to be propelled with Fermilab superconducting radio frequency technologies.

The $100,000 award by DOE’s Office of Technology Transitions and the Office of Fossil Energy and Carbon Management will continue the work done by Thangaraj and Daniel Bowring during their participation in the third cohort of the DOE Office of Technology Transition’s Energy I-Corps program. The Energy I-Corps program trains national lab researchers to evaluate industry needs and potential market applications for their technologies.

”DOE’s Energy I-Corps program offers Fermilab researchers the opportunity to explore the potential of technologies we develop for particle physics to be applied to other applications,” said Cherri Schmidt, the manager of Fermilab’s Office of Partnerships and Technology Transfer who pioneered the Energy I-Corps teams at Fermilab. “With this additional funding, we can research and develop one of the key components of our compact SRF accelerator—the electron source—and take the next step toward commercial applications.”

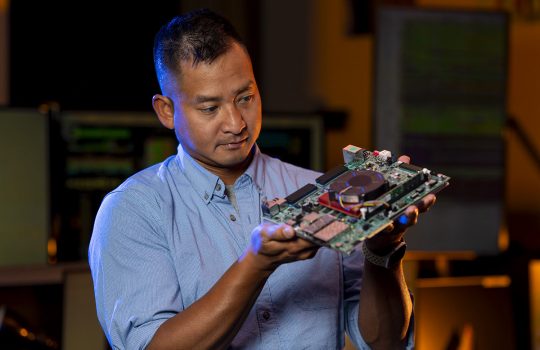

Thangaraj and the team at the Illinois Accelerator Research Center, known as IARC, aim to combine small-scale cryogenic and superconducting technologies in the development of compact accelerator prototypes. It will make compact accelerators more efficient and feasible than current state-of-the-art compact accelerators.

“I am thrilled to receive this award from DOE OTT and FECM, which will allow us to take the next step in the commercialization of our work at Fermilab in compact accelerators,” said Thangaraj, who is a senior technology development and commercialization manager at Fermilab.

“We are bringing together some of the most cutting-edge technologies to radically simplify the cooling infrastructure in our machines, which makes it attractive for commercial applications,” said Thangaraj. “There is always a challenge whenever you try something innovative, but that is also where the opportunities and fun are.”

Charles Thangaraj stands next to a superconducting cavity that will accelerate electrons in a compact accelerator. Photo: Tom Nicol, Fermilab

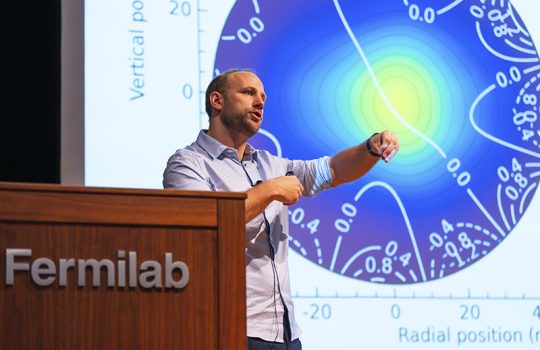

Compact accelerators for industry

The compact accelerators under development at Fermilab are about the size of a conference room table and capable of delivering high-energy electron beams, up to 10 million electron volts, and high power up to 1 megawatt.

“Based on our market research and conversations with industry, we know there is a demand for machines that can deliver beams of high-energy electrons for a variety of applications,” said Chris Edwards, engineering project manager at Fermilab.

One such use case is metal 3D printing, which involves laying down metal powder and fusing the added metal with an electron beam. Refractory metals, such as tungsten, tantalum and niobium, are resistant to heat and wear. They hold significant manufacturing value in the energy and aerospace industries.

The same properties that allow refractory metals to perform under harsh conditions create significant barriers to metal 3D printing. Fermilab’s compact SRF accelerator technology shows promise to overcome these obstacles.

“Compact accelerators are extremely versatile. Even though we are currently focusing on a few specific applications, these machines can have a far wider range of uses,” said Edwards.

Along with metal 3D printing, Fermilab scientists are also developing compact accelerators to treat and reinforce asphalt for roads.

By incorporating molecular chains into asphalt mixtures and blasting the asphalt with a beam of electrons, construction companies could make roads and infrastructure more durable.

This setup would involve placing a compact accelerator on the back of a truck. The compact accelerator would launch beams of electrons downward toward the asphalt.

“We feel it is crucial that we leverage the power of technology to spur economic growth, foster community development and create an environment of innovation. The IARC team, OPTT and Fermilab management are encouraged by the DOE support and commitment to these endeavors,” said William Pellico, IARC director.

Fermi National Accelerator Laboratory is supported by the Office of Science of the U.S. Department of Energy. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, please visit science.energy.gov.