Although it often goes unnoticed, Americans rely on specific industries to carry out important, life-saving tasks such as sterilizing medical equipment. These processes require powerful sources of irradiation, and in some cases, radioactive materials are used, which require special handling and can be dangerous. As a result, there is a growing need for cleaner, safer alternatives. One promising solution is electron beam accelerators.

Researchers at the Department of Energy’s Fermi National Accelerator Laboratory recently received funding from the National Nuclear Security Administration’s Office of Radiological Security to explore how electron beam accelerators can be more widely adopted for medical device sterilization.

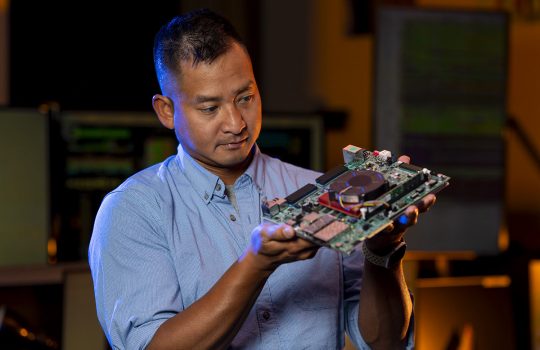

“This is a significant opportunity to explore the potential of highly efficient, clean and safe electron beam technology,” said Charles Thangaraj, technology development manager at Fermilab and the project’s principal investigator. “Electron beam technology offers a more secure and flexible alternative to traditional radioactive sources for sterilization and environmental applications.”

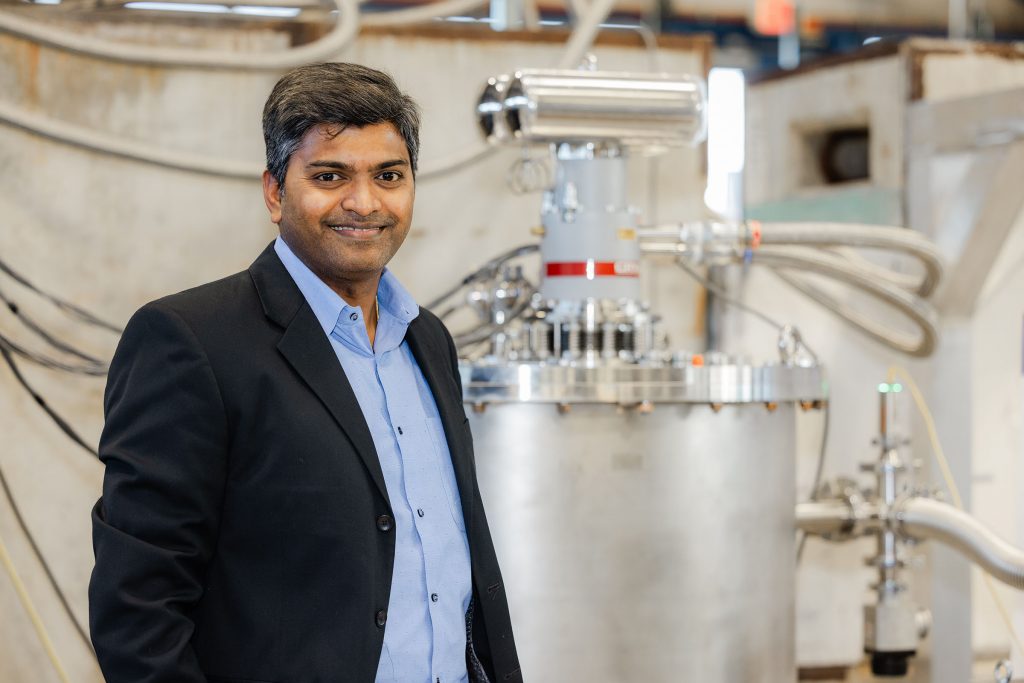

Fermilab has previously received funding from NNSA’s Office of Defense Nuclear Non-Proliferation for related projects. One current initiative involves Thangaraj and his colleagues developing a prototype electron beam accelerator. This superconducting radiofrequency machine accelerates electrons to produce high power levels while minimizing energy loss. Once built, this prototype could pave the way for production of a higher-powered accelerator, which could be used for sterilizing medical equipment.

The new Office of Radiological Security funding allows the project team to explore multiple pathways toward adopting non-radiological accelerators like the SRF prototype. The team will leverage their expertise in accelerator technology and experience engaging stakeholders to help companies make well-informed decisions about transitioning away from reliance upon radioactive materials.

Although this project primarily targets medical device sterilization, its benefits could extend across multiple industries. For example, similar electron beam accelerators could be used to sterilize fruit, improving safety in processing and shelf life.

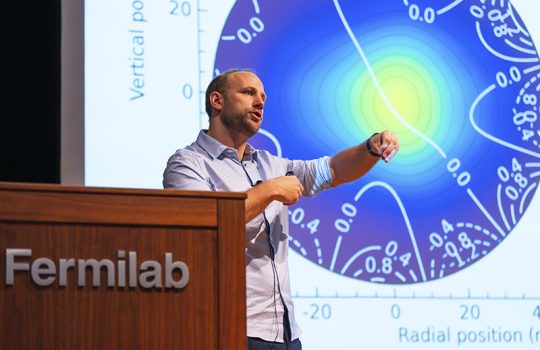

Fermilab brings a unique set of skills to overcome the barriers that limit use of modern electron beam accelerators. The laboratory’s engineers, scientists and business specialists have extensive experience working with industry and government stakeholders and have facilitated collaboration among medical device industry experts, accelerator manufacturers and federal agency representatives through workshops and events.

Fermilab engineering project manager Chris Edwards, a co-principal investigator on the project, points out that higher-powered electron beam accelerators are attractive to companies because a higher amount of materials or product can be treated in the same timeframe as current processes. However, to ensure the accelerators can be widely adopted, several factors need to be addressed.

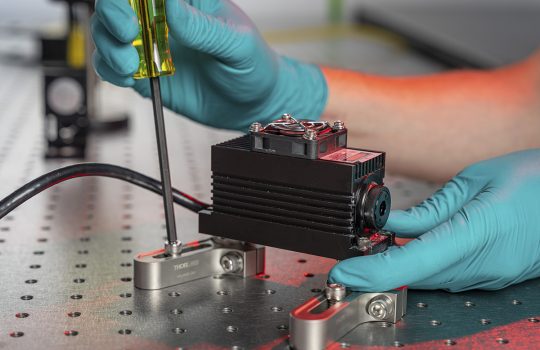

Initially, an analysis is needed to compare the various radiofrequency sources. The team will evaluate both modern and legacy radiofrequency sources, such as klystrons, which are typically used for industrial accelerators today, and magnetrons.

“When you’re looking at these high-powered machines that Fermilab is designing and building, you need a good RF source to power the machine,” said Edwards. “SRFs really shine at these higher powers, which some machines currently in use can’t even reach,” said Edwards.

To gather insights, the team will leverage their established industry connections to interview industrial accelerator users and operators, collecting data about companies’ needs, challenges and concerns — particularly around energy efficiency, reliability and the lifespan of accelerators. With this information, they will analyze RF sources to determine which are financially feasible and readily available for industry adoption.

“We want to make sure that, as we move forward with these higher power machines, we have the right technology for the RF power source selected that industry wants to see,” said Edwards.

Another challenge to broader adoption of electron beam accelerators is the need for a clear plan to transition existing RF sources to new ones. This shift could lead to operational disruptions and delays if not properly managed. To address this, the team will create a comprehensive transition roadmap, identifying potential issues such as supply chain challenges and operational hurdles, enabling companies to plan effectively for the shift to modern accelerators.

While high-power electron beam accelerators are currently limited to a few scientific and research facilities, widespread adoption will require a workforce trained in operating and maintaining these advanced machines. Technicians and scientists will need education in troubleshooting, safety and other key skills.

Tom Kroc, a Fermilab scientist who has been instrumental in both developing electron beam SRF technology and engaging with the medical device industry, will lead the training and development efforts.

“We hope to work with two industry-specific societies to engage with local educational institutions to develop curricula,” said Kroc. “In addition, we will work with education, industry and government partners to create training standards and develop a training strategy for this new workforce.”

Finally, the project team will develop a business plan for establishing an electron beam technology hub that will promote the advancement and adoption of electron beam technology by bridging the gap between research and industry. It will provide essential resources such as R&D support, testbeds, prototyping, regulatory compliance assistance, and workforce training, all fostering collaboration between accelerator experts and industry professionals.

“Our mission is to take Fermilab’s technology, developed in the pursuit of scientific research, and apply it to solving emerging problems in industry. Through this opportunity from ORS, Fermilab is well positioned to explore industry adoption of modern electron beam technology,” said Thangaraj.

Fermi National Accelerator Laboratory is America’s premier national laboratory for particle physics and accelerator research. Fermi Forward Discovery Group manages Fermilab for the U.S. Department of Energy Office of Science. Visit Fermilab’s website at www.fnal.gov and follow us on social media.