Powerful particle accelerators can enable important scientific discoveries. They can also safely sterilize medical equipment, remove dangerous chemicals from water and soil and eradicate harmful organisms from fruits and vegetables. However, even the mightiest machines can be felled by a single weak link. As higher-powered and more expensive accelerators are being increasingly sought after for use in science and industry, researchers are seeking ways to make them more reliable and optimize the return on investment.

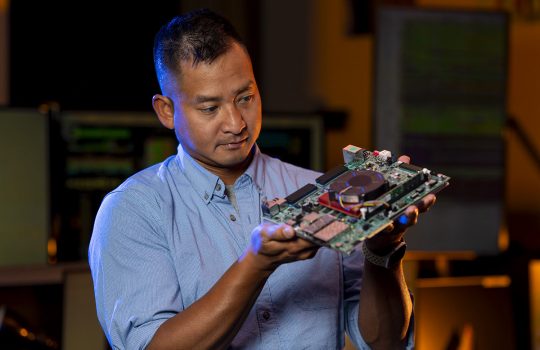

Engineers at the U.S. Department of Energy’s Fermi National Accelerator Laboratory are drawing on decades of experience designing, building and operating superconducting radio-frequency accelerators to deliver higher powered machines with greater reliability for broader scientific and industrial use.

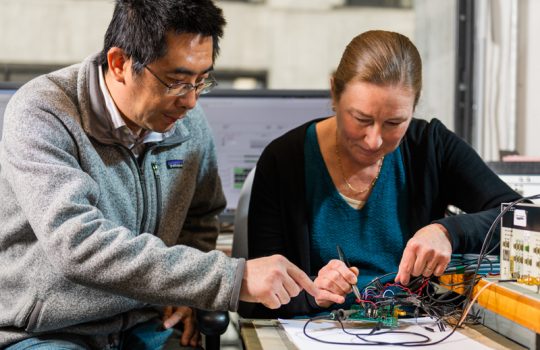

In a multi-year project led by engineers and scientists at Fermilab’s Illinois Accelerator Research Center, or IARC, the team worked with Euclid Techlabs, an industry research lab that specializes in superconducting radio-frequency technologies and materials. One of IARC’s missions is to engage in commercialization of technology.

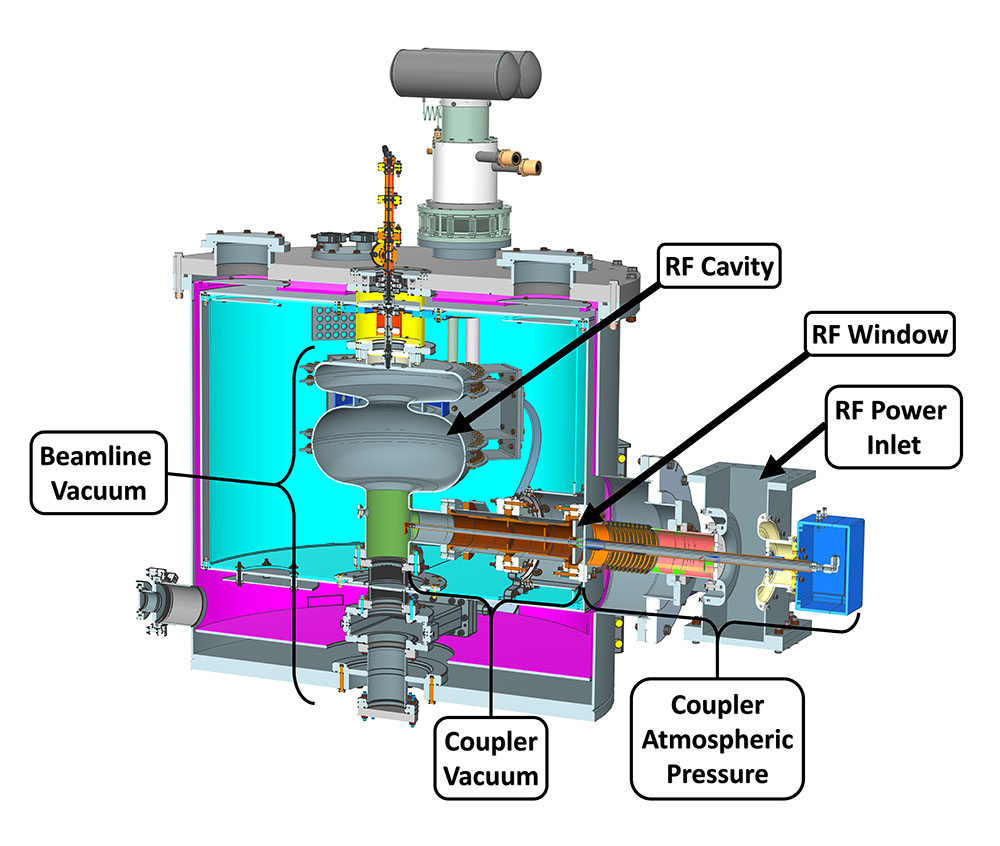

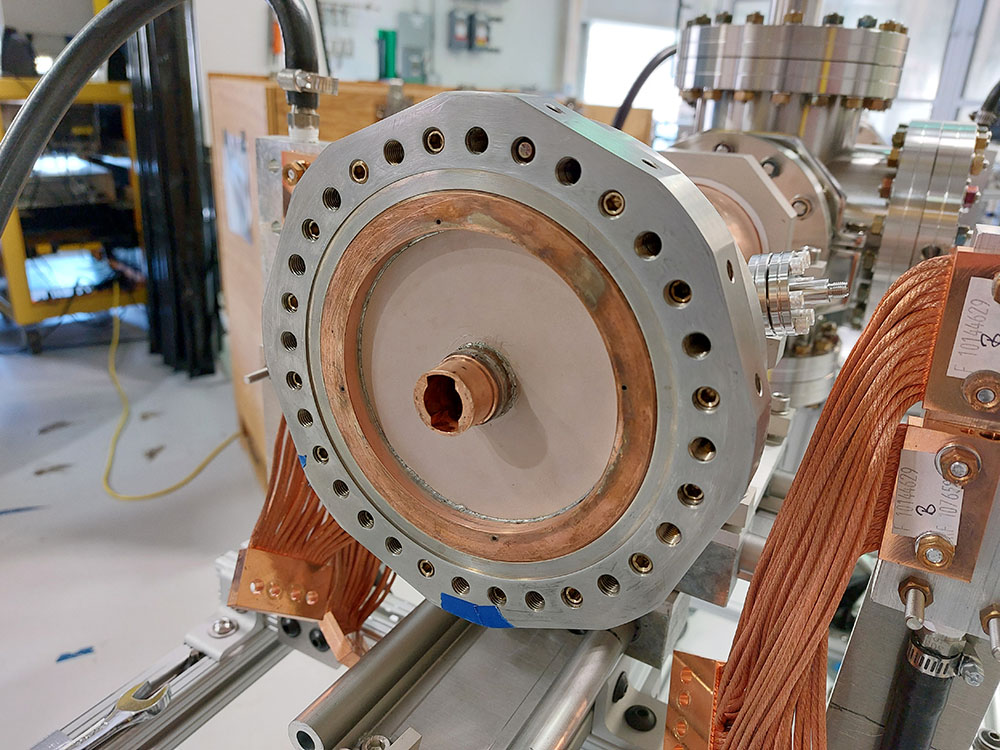

The research team tested a new slightly conductive ceramic for use in a key accelerator component called the radio frequency window. The RF window is part of the power coupler that delivers radio-frequency energy to the accelerator from an external power supply. Within the accelerator cavity, the radio-frequency energy speeds up the particles.

RF couplers have two sides: one connected to the vacuum-sealed accelerator cavity and the other exposed to atmospheric pressure. The ceramic RF window acts as a barrier between these environments.

“It’s similar to a window in your home where you can see through, but it doesn’t allow cold air from outside to get in,” said Chris Edwards, a Fermilab IARC engineer who is involved in industrial SRF development. “In an accelerator, the RF window allows the power to pass through but prevents the atmospheric air from leaking into the vacuum side. Even negligible leaks would cause the accelerator to become damaged or inoperable.”

Because RF energy cannot pass through metal, the RF window must be constructed of ceramic, which is attached to metal conductors both inside and outside by brazing. The ceramic allows high energy RF power — typically around 50 kilowatts at Fermilab — to pass through, with future accelerators requiring even higher power levels.

However, ceramic is an insulator, meaning it does not conduct electric currents. This can cause the buildup of charged particles such as electrons on its surface, leading to electrical breakdowns that can destroy the window.

“As we move to higher and higher-powered accelerators, there’s a greater risk of the ceramic being damaged, so it’s very beneficial to us to have more reliable ceramic windows for our RF couplers,” said Sergey Kazakov, an engineering physicist at Fermilab who worked on this project.

To this end, Euclid Techlabs used its expertise in ceramic materials and manufacturing processes to develop technology that makes the ceramic slightly conductive — just enough to remove the accumulated electrical charge from the ceramic surface and volume while keeping the ceramic RF energy losses small enough for this application. Euclid Techlabs provided the Fermilab team with a power coupler built using the new type of ceramics.

“This new, conductive ceramic is as good or better than traditional alumina ceramic windows, and prevents the problems associated with charging,” said Ben Freemire, a scientist at Euclid Techlabs.

Fermilab tested the prototype in its facility with promising findings.

“The results were very good,” said Kazakov. “The coupler testing reached 80 kilowatts full reflection. The power was limited by the test facility, not the coupler. By focusing on one of the riskier components of SRF accelerators, a more reliable ceramic was produced and tested that can help the accelerator remain operational and reduce the risk of parts being damaged.”

The next step, according to Fermilab IARC engineer and project leader Josh Helsper, is to further improve the RF window so it can eventually be used in an actual SRF accelerator. This requires the ability to securely attach the ceramic to a copper sleeve. While the original prototype was soldered, the final product will use brazing — a process that involves heating metal joint surfaces and a filler metal to higher temperatures to create stronger connections.

“Soldering is useful for testing proofs of concept, but brazing is needed for use in real-world accelerators,” explained Helsper. “Brazing is the preferred connection method because it can connect dissimilar metals, and the higher temperatures used in brazing enable the copper to fuse to stronger materials typically used in accelerators like the gold-copper or silver-copper mixtures.”

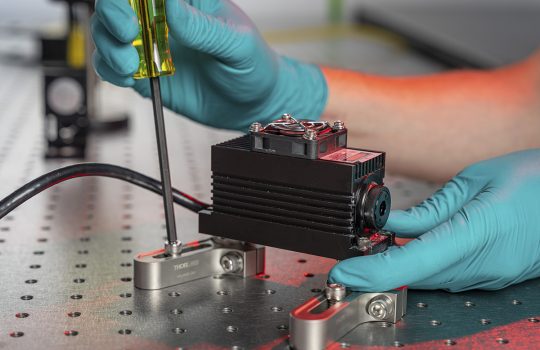

Brazing these components requires special facilities and equipment that can achieve temperatures around 1,832 degrees Fahrenheit (1,000 degrees Celsius), and the process is performed in a vacuum to prevent oxidation. Euclid has tested the electrical conductivity and the power leak rate of a newer version of brazed conductive ceramic and found that they are satisfactory for an SRF accelerator.

Now that they have successfully tested the new ceramic material and brazing process, the Fermilab team will be seeking a power coupler manufacturer to standardize the production of brazed ceramic RF windows.

“This work was essential to advance industrial SRF technology and part of the leading-edge work that Fermilab does. This positions us well for our future accelerators,” said Edwards.

Fermi National Accelerator Laboratory is America’s premier national laboratory for particle physics and accelerator research. Fermi Forward Discovery Group manages Fermilab for the U.S. Department of Energy Office of Science. Visit Fermilab’s website at www.fnal.gov and follow us on social media.