Balloons can help make a space perfect for a party. Now they also can help when it comes to accelerating particles to near the speed of light.

The innovative use of balloons provides a new, patented way for engineers to shape the metal heart of particle accelerators.

Many particle accelerators use structures called cavities, which provide the kick needed to accelerate particles to higher and higher energies as the particles barrel through one after the other. Situated deep inside an accelerator and cooled by a shell containing liquid helium, cavities have to be just the right shape and size to boost particles to the desired energies. Even small differences in the shape of these metal chambers make large differences in the electric fields that are generated inside the cavities to push particles to greater speeds.

Faced with one particular cavity that was too misshaped to use and inaccessible because of its metal shell, Fermilab engineers Mohamed Hassan and Donato Passarelli got an idea: What if you could reshape a cavity without removing the surrounding shell? They went to work, developing an innovative process called balloon tuning.

“I hope balloon tuning is an example for the accelerator community — that we should think out of the box and not always stick with the standard and common technique,” said Passarelli.

The patented balloon tuning process is a new option in the suite of techniques used to prepare cavities before they’re installed in an accelerator.

Fermilab engineers Mohamed Hassan, left, and Donato Passarelli stand near an accelerator cavity and the patented balloons used to tune, or reshape, the cavity from the inside. Photo: Reidar Hahn

Most acceleration cavities are a series of round, hollow cells that look like a giant strand of metal beads. Before any cavity is installed, it is carefully tested and tuned using an automated machine that grasps the edges of each cell to make small, precise adjustments: a little push here, a little stretch there. The process continues until the cavity is adjusted so that, once the cavity is up and running inside an accelerator, it’s in the shape to produce the perfect electric field to propel charged particles.

But before most cavities can be installed, they must also be fitted with a metal jacket so the cavity can be cooled to extremely low temperatures with liquid helium. After that, the only easy way to apply forces to the cells is to push or pull on the ends of the cavity, rather than targeting each cell individually. If a cavity becomes misshaped during or after the process of putting the jacket on, the traditional tuning method can’t be applied without cutting the metal jacket off — a laborious, time-consuming task.

Hassan and Passarelli started contemplating this challenge after an old test cavity deformed during a pressure test.

“After the pressure test, I was determined to find a way to fix this cavity and thought, ‘Why not access it from the inside, which is accessible even with a jacket?’” Hassan said.

The need to apply the force inside the cavities without scratching the inner surface or introducing unacceptable levels of contamination led them to using specially designed balloons made of rubberized nylon.

A pump fills each balloon with air until it applies about two bars of pressure — a little less than what’s recommended for standard car tires. This isn’t enough pressure to reshape a cavity cell on its own, but that pressure can be used to influence which cell deforms when forces are applied to the ends of a cavity at room temperature. Balloons let you single out a particular cell, either stretching or squeezing it.

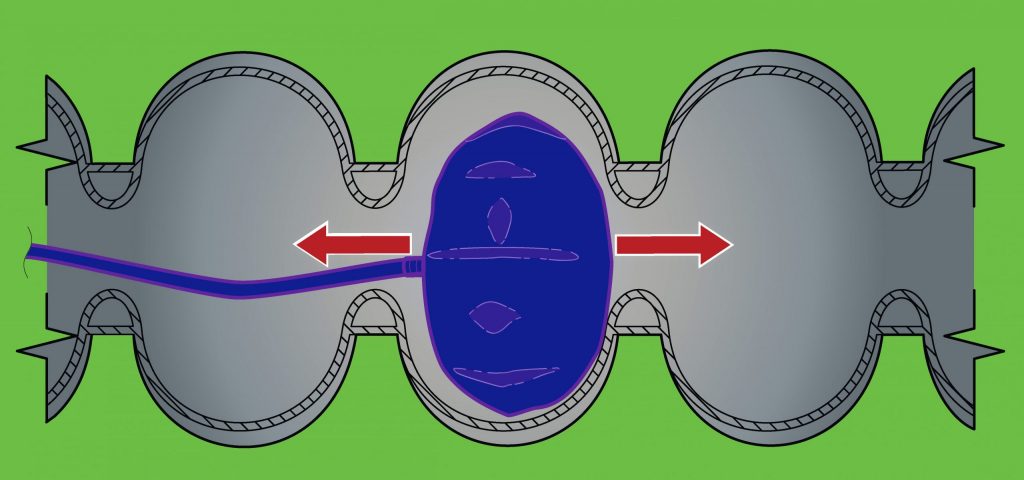

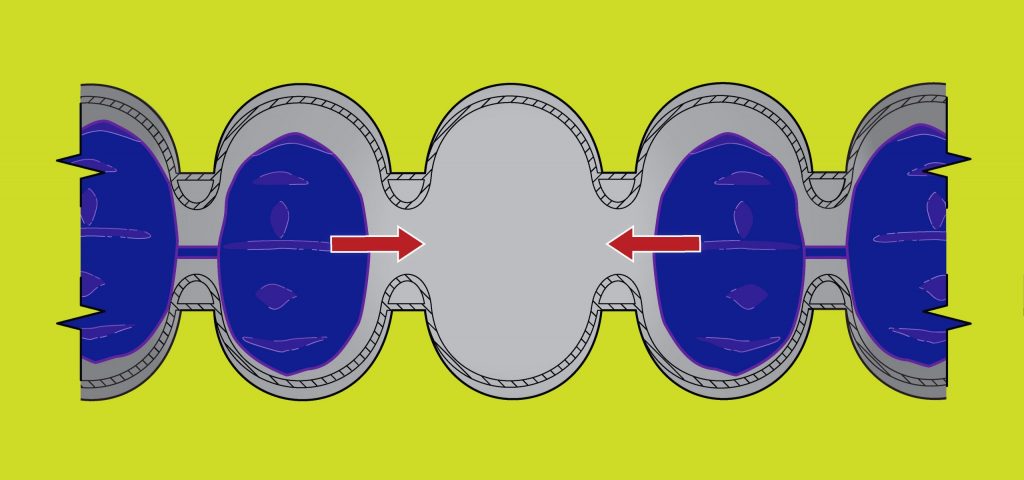

If a particular cell needs to be stretched, a balloon inflated inside it provides an extra nudge for it to expand as the flanges are pulled apart. Whereas if a cell needs to be squeezed, a series of balloons can support all the other cells as the two ends are pushed together.

To stretch one cell of an accelerator cavity, a balloon is placed inside it and inflated. Image: Diana Brandonisio

To squeeze a particular cavity cell, balloons are placed inside the cells surrounding it. The balloons support these cells, resulting in the unoccupied cell being reshaped as forces are applied to each end of the cavity. Image: Diana Brandonisio

The engineers and their team demonstrated the concept by tuning an unjacketed cavity. Then they turned their attention to the misshaped cavity that had inspired them to develop the process. They succeeded in returning it to usable condition.

“Balloon tuning will be a nice additional tool for cavity production that can save quite a bit of money and time,” Hassan said.

High-performing cavities are crucial components in Fermilab’s upcoming PIP-II accelerator and SLAC National Accelerator Laboratory’s LCLS-II X-ray laser, and they are a major part of a current Fermilab project to extend the time that a qubit can maintain information.

The balloon-tuning technique was recently patented, speeding through the patent office in record time for Fermilab, said Aaron Sauers, the lab’s patent and licensing executive.

“Mohamed and Donato developed a truly beautiful method and apparatus to tune dressed cavities,” Sauers said. “I was excited to file the patent application on their invention.”

Hassan and Passarelli see automated balloon tuning as a possibility, which could make it as convenient to use as the current method is for unjacketed cavities. The technique may also find applications in other fields that use similar cavities.

“The hope is that people looking at this idea will get inspired and either adapt or use this technique in their own application,” Passarelli said.