This article is dedicated to our dear friend and colleague Gino Bolla.

The Dark Energy Spectroscopic Instrument, called DESI, has an ambitious goal: to scan more than 35 million galaxies in the night sky to track the expansion of our universe and the growth of its large-scale structure over the last 10 billion years. Using DESI — a project led by Lawrence Berkeley National Laboratory — scientists hope to create a 3-D map of a third of the night sky that is more accurate and precise than any other.

A precise map requires that DESI itself be built and assembled with micrometer precision. Fermilab, a Department of Energy national laboratory, is contributing a key piece of the instrument: a large, barrel-shaped device that will hold optical lenses to collect the light from millions of distant galaxies. The smallest deviation in lens alignment could lead to the instrument being permanently out of focus. Every piece of the barrel must be perfectly placed, so the Fermilab team is currently taking every measure to ensure its precise assembly.

The process involves a special machine, meticulous handling and a healthy dose of patience.

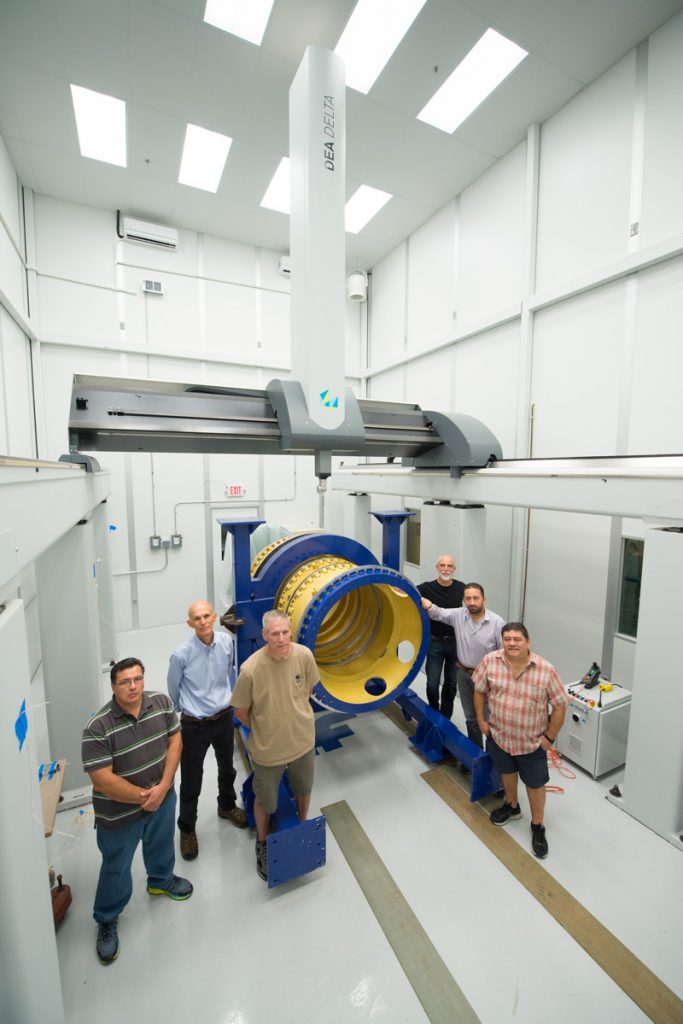

This Fermilab team is currently assembling the barrel for the Dark Energy Spectroscopic Instrument, a project being led by Lawrence Berkeley National Laboratory. From left: Jorge Montes, Mike Roman, David Butler, Gaston Gutierrez, Giuseppe Gallo, Otto Alvarez. Photo: Reidar Hahn

Precision assembly

The lens-holding device is a roughly 8-foot-long and 4-foot-wide segmented cylinder — about the size of a small elevator. Once the hulking steel barrel is complete, it will be installed at the Mayall four-meter telescope at the Kitt Peak National Observatory, southwest of Tucson, Arizona.

The lenses will collect the light reflected from the telescope’s mirror and focus it into 5,000 optical fibers, through which the light is transported to special detectors, called spectrographs. With the help of 10 such spectrographs, scientists can measure the distance of the galaxies.

In May, a team of specialists at Fermilab began assembling the barrel’s five segments carefully, checking that each nut and bolt was perfectly situated. But a nuts-and-bolts-level fit isn’t enough. To achieve the precision scientists are aiming for, the DESI barrel and its inner structure must be assembled accurately to within an incredibly tight 20 micrometers. That’s one 10th of the thickness of a sheet of paper.

To achieve the required fit, the team has been making small, critical adjustments to the assembled barrel.

Accurate alignment

The barrel adjustments take place in a vacant area the size of a small bedroom. Four tall pillars – nearly seven feet high – stand at the corners of the space.

Above their heads, a rail, similar to train tracks, connects the tops of the two pillars on one side. A second rail connects the other two. A moveable carriage track spans the gap – like a high bridge spans a river – connecting the two rails. The carriage itself glides along the track.

The team guides the carriage so that it stops just above the barrel. The carriage carries a mechanical arm that points towards the floor. It can rotate in all directions in the space within the pillars. At the end of the arm is a highly sensitive and precise sensor, fixed to an articulating motorized probe.

The arm with the sensor comes to life: It reaches down to the barrel and starts feeling for its surfaces. It searches for specific points on the barrel – a corner, an edge, another significant surface marker. When it finds them, it measures the coordinates in the designated space. Very carefully and with tiny movements, it moves over the whole surface of the barrel, measuring up, down and around the surface. As it does, it records the measurement data and saves it for further analysis. Jorge Montes, one of the team members, strategically places markers on the barrel’s surface to assist their alignment efforts.

After making the measurement, the scientists return the barrel to an outside area. There they disassemble it, realign all the parts, relying on the previously placed markers. They then reassemble it. With great care they bring the once more fully assembled barrel into the empty space and measure anew the precision of their assembly.

Comparing their performance with their previous assembly, they learn which pieces, if any, are misaligned — even slightly — and where they improved the alignment.

The barrel will hold the lenses and optics for DESI, which will map one-third of the night sky. To create an accurate map, the barrel’s pieces must be accurately assembled to within 20 micrometers. Dial Machine of Rockford, Illinois, manufactured the barrel steel components. Its many tons of steel work were machined to the incredible accuracy required. Photo: Reidar Hahn

A magic machine

The precise, slow-moving measuring machine that points out the misalignments is called a coordinate measuring machine, or CMM. The group making these point-by-point measurements, led by Fermilab engineering physicist Michael Roman, uses it to ensure the DESI barrel’s perfect assembly.

With the help of the CMM, they repeat the whole procedure of assembly, measurement and disassembly again and again, always comparing their performance against previous tries. When they reach their alignment within 10 micrometers — about a 10th the width of a human hair — in a certain number of tries, they are satisfied.

“From early on we knew that the barrel needed high-precision measurements for the assembly and that it would be too large for any of the CMMs at Fermilab to perform such measurements,” Roman said.

“In strong support of DESI, Fermilab bought a machine for the dedicated measurements on the barrel,” said scientist Gaston Gutierrez, who is one of the DESI project leads at Fermilab.

Steady and stable

To ensure that the CMM’s measurements are as precise as they need to be, the CMM is set up in an air-conditioned room, where scientists monitor and control the temperature 24 hours a day. Materials expand when they get warm, affecting the accuracy of CMM’s measurements.

So scientists worked out the right control settings for the environmental control system to ensure that the temperature never varied more than one degree from 20 degrees Celsius.

Even the eventual effect of heavy weights on the DESI barrel, including the lenses, can be measured with the new CMM. Scientists place the DESI barrel in the machine and measure it, then add test weights on its sides and remeasure. The team can see how the barrel shrinks or bends, if at all, and determine whether the lenses will hold steady when the telescope is in motion.

The Fermilab team expects to finish all CMM measurements by early 2017. Then they will disassemble the DESI barrel and send it to University College London. In London, their colleagues will install the lenses in the support structures. Once the lenses are installed, the barrel will start its journey to its future home in Arizona.

Measuring the expansion of the universe

Scientists have discovered that our universe is growing bigger and bigger — without any end in sight. Like raisins in a rising loaf of bread, the universe’s galaxies are being pushed apart from each other.

From previous measurements, scientists have a kind of cosmic ruler, a standard length that goes back to the universe’s early beginning. Using this ruler together with the high-precision DESI map, scientists will be able to tell how far galaxies have moved apart and how much our universe has grown throughout its history.

“With the DESI experiment, we want to follow the growing steps of our universe,” Gutierrez said. “We start from today and go backwards in time to measure how much the universe has expanded since its early days.”

The fabrication, assembly and operation of DESI are small but highly important steps toward precisely understanding the universe.