The manufacturing of a component of a particle accelerator at the Department of Energy’s Fermilab has been recognized for excellence in casting design.

The American Foundry Society and Metal Casting Design & Purchasing magazine named the prototype part one of its 2019 Casting of the Year winners in the category Achievement by a Small Foundry.

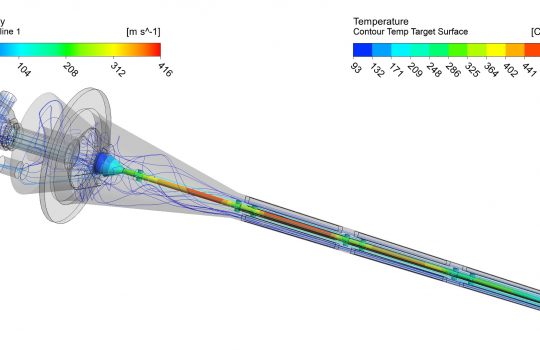

Fermilab engineers provided Michigan-based RoMan Manufacturing with a design of a support mount that sits inside a crucial structure for accelerating particles called a cavity.

Previously, the structure was milled from solid copper blocks and welded together.

Matt Slabaugh inspects a prototype of an accelerator cavity support mount. RoMan Manufacturing fabricated the part using a 3-D-printed mold. Photo: Reidar Hahn

Now the Fermilab team is pursuing new, cost-saving manufacturing methods. The laboratory contracted a foundry to test a new way of creating the component. RoMan Manufacturing used a 3-D-printed sand mold of the part and then poured copper into it to make the prototype.

“Traditional casting techniques for a single piece often require special tooling and machining, and a structure of this size is labor-intensive,” said Fermilab engineer Matt Slabaugh.

Producing the part with a 3-D-printed sand mold costs roughly one-fifth of the price of the milling method, and production time goes from many months to a few weeks.

“This was quite a feat. It’s not easy to fashion copper into a shape like this, let alone to the precise specifications we needed,” said Fermilab engineer Bill Pellico. “So the method is promising, especially since copper is such a common component in accelerating cavities.”

The company’s successful prototype fabrication points to more economical options for creating accelerator parts.

This accelerating cavity support mount was made using a 3-D-printed sand mold. It received a 2019 Casting of the Year award. Photo courtesy of Modern Casting Magazine, a publication of American Foundry Society

“While the method is still new to us, it’s a possible first step on a path to using 3-D-printing technology to make accelerator components faster and cheaper,” Pellico said.

It’s also a demonstration of the mutually beneficial partnership between laboratory and industry. Fermilab works with industry partners to fill a need in particle physics, adapting and improving technologies to advance the field. The resulting innovation often finds its way into the company’s offerings to other customers, an improvement that reaches beyond particle physics to a broad spectrum of industrial applications.

The award-winning combination of old and new design techniques may become a solution for cutting-edge science.

“Copper casting is one of the oldest known metal forming techniques,” Slabaugh said. “Enhanced with modern 3-D printing technology, it shows potential as a unique solution for our accelerator.”