Fermilab scientists and engineers have achieved a landmark result in an ongoing effort to design and build compact, portable particle accelerators. Our group successfully demonstrated a new, efficient way to cool superconducting accelerator components, cutting down on the bulk of the traditional cooling infrastructure needed for this technology.

The importance of this advance is apparent if you happen to walk around the Fermilab site. You really can’t miss it: Particle accelerators built for discovery are big machines. They stretch for hundreds of meters, even kilometers. They also require large and complex infrastructure, which restricts their use primarily to science research laboratories.

And yet, particle accelerators are very useful tools outside science research labs. They have applications in security, medicine, manufacturing, and roadways. And their impact might be even greater if we could make these traditionally giant machines compact. Miniaturize them. Design high-power accelerators that could fit, literally, inside the back of a truck.

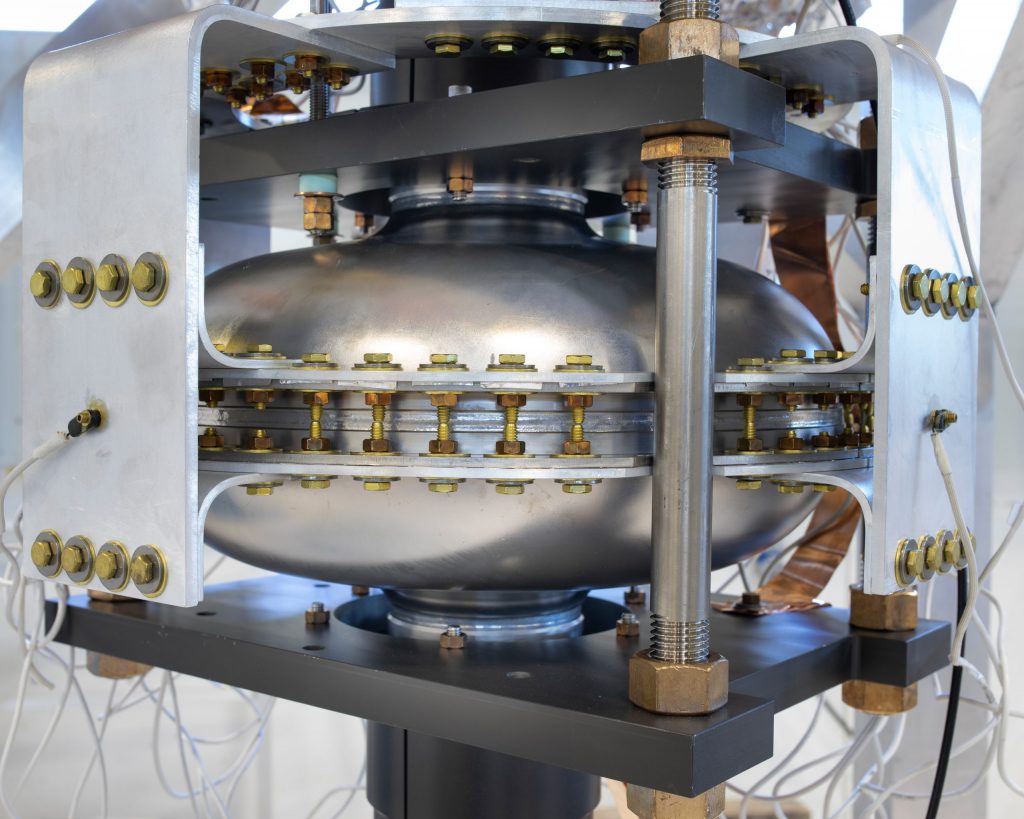

For the first time, a team at Fermilab has cooled and operated a superconducting radio-frequency cavity — a crucial component of superconducting particle accelerators using cryogenic refrigerators — with cryocoolers, breaking the tradition of cooling cavities by immersing them in a bath of liquid helium. It achieved an accelerating gradient of 6.6 million volts per meter. Photo: Marty Murphy

At Fermilab, we relish such practical physics challenges. And last month, our team rose to the challenge, achieving a major milestone in our quest to realize powerful, compact accelerators that have an impact on our everyday lives. The core team included Ram Dhuley, Michael Geelhoed, Sam Posen and Charles Thangaraj.

Combining a verve for practicality with cutting-edge science, our team successfully demonstrated a new, revolutionary method for cooling a superconducting accelerator cavity without using liquid helium — counterintuitive for most in accelerator science.

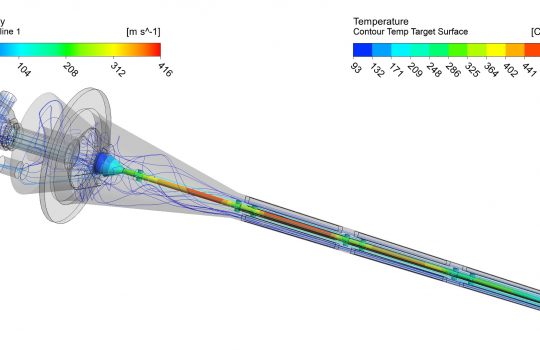

This new method — based on a Fermilab idea patented five years ago — uses cryogenic refrigerators, or cryocoolers, for removing the heat dissipated by a superconducting accelerator cavity. By compressing and expanding helium gas across a regenerative heat exchanger in a “closed” cycle, the cryocoolers produce cooling without letting the helium out. This closed-cycle operation of cryocoolers makes our system very compact — more so than the standard liquid helium cooling equipment used by traditional accelerator cavities.

Superconducting cavities are crucial components in particle accelerators, propelling the particle beam to higher energies by giving it an electromagnetic push. We used a 650-megahertz niobium cavity, and we all watched with pride the first successful results delivered by our new method: an accelerator gradient of 6.6 million volts per meter. That is already sufficient for the applications we have in mind, and still, we know we can do better.

Superconducting cavities used in large accelerators are usually cooled to around 2 kelvins, colder than the 2.7 kelvins (minus 455 degrees Fahrenheit) of outer space. The typical way to achieve this is by immersing the cavities in liquid helium and pumping on the helium to lower its pressure, and therefore its temperature. All of this requires large and complex cryogenic systems – a factor that severely limits the portability and therefore the potential applications of superconducting accelerators in industrial and other environments.

Celebrating the success of the first results from the conduction-cooling project are, from left: Michael Geelhoed, Ram Dhuley, Sam Posen and Charles Thangaraj. Photo: Laura Rogas

Our team broke this barrier by successfully realizing a technique conceptualized by Fermilab physicist Bob Kephart, now retired. The technique proposed to make superconducting accelerators practical by 1) coating a thin layer of a material called niobium-tin to the inside of the niobium cavities, and 2) cooling the coated cavities using cryocoolers via conduction links connecting the two. The cryocooler-cavity setup dispenses with a bath of cryogenic liquid and any need for a cryogenic plant to achieve superconductivity.

The demonstration also shows how this method could simplify superconducting accelerators and make them accessible for broader needs beyond basic science – better pavements, wastewater treatment, medical device sterilization, and advanced manufacturing.

Applying the scientific breakthroughs at Fermilab and transforming them to solve challenges outside fundamental science involves systematic entrepreneurial thinking – identifying an opportunity and asking and answering a whole host of questions to validate the opportunity. A great value in all of this is converting DOE’s investment in science and technology into innovation that could allow new industries to emerge.

At Fermilab, we will continue to apply our frontier technologies for novel applications beyond discovery science. This major breakthrough is an exciting step in that direction, and we will continue to push the envelope.

This project is supported by the Laboratory Directed Research and Development Program at Fermilab. The work is also supported by the DOE Office of Science.

Charles Thangaraj is the science and technology manager at Fermilab’s Illinois Accelerator Research Center.