At the Sanford Underground Research Facility in Lead, South Dakota, site of the former Homestake gold mine, technicians and engineers are employing a modern approach to moving massive steel beams for the Deep Underground Neutrino Experiment, hosted by the U.S. Department of Energy’s Fermi National Accelerator Laboratory.

The unique system they have constructed is an air cart — a hovercraft using air casters that each generate little more force than a push from a person’s hand to create a foundation of compressed air for floating heavy items above the ground.

“It seems like it shouldn’t work, but it does,” said Jeff Barthel, a rigging specialist at SURF. “I think in our final setting we ended up with a beam that weighs about 12,000 pounds. It’s amazing, that it only takes about 10 to 20 pounds per square inch of pressure on each caster, just a little bit of concentrated air pressure, to float this heavy object on air.”

With a nod to the history of the former Homestake Mine, the team named the air cart “Maggie II” in memory of a beloved workhorse that 120 years ago was renowned for her prowess in helping miners move large amounts of material.

“Maggie carried more gold ore during the days of Homestake than any other animal,” Barthel said. “This air cart is going to transport more than one thousand pieces of steel, so we thought we should call it Maggie II. It’s a fitting tribute to the past.”

From dreams to design

The air casters that support the hovercraft at SURF were engineered for the specific purpose of moving 1,124 steel beams that are needed to construct cryostats for the largest international physics experiment ever undertaken on American soil. The Long-Baseline Neutrino Facility/Deep Underground Neutrino Experiment (LBNF/DUNE) is currently being built in Illinois and South Dakota. As in many great undertakings of science and engineering, logistical and technical problems yield novel solutions. Air casters have been around since the 1960’s and engineers found they were the right fit for this job.

“The design started as pretty basic, with just wheels and a cart,” said Sanmitra Pingulkar, a Fermilab mechanical engineer. “This didn’t work because the load was too heavy, and the ground is uneven. One person on our team had used air casters before, so he floated that idea as a solution.”

The air casters proved effective not only for managing the heavy weight, but also for the awkward shape of the steel beams — many of which are shaped like a gigantic letter L.

“The L-beam has three characteristics that make it tough to work with: it’s heavy, it’s very narrow, and it has a very high center of gravity,” said Barthel. “The air caster addresses all of those things.”

For instance, if crews were to place the L-beam directly in the center of the cart, only two of the air casters would sustain the majority of the load. This resulted in an unstable method of transporting the beam to the cage — an elevator for delivering material more than a mile underground.

“The L-beam is difficult,” said Pingulkar. “Depending on where you place the beam, you get different weight distribution on the cart. Eventually, we found a way to distribute the weight that was a 30/70 split, which provided greater stability for the cage while transporting it underground.”

A small role in a huge undertaking

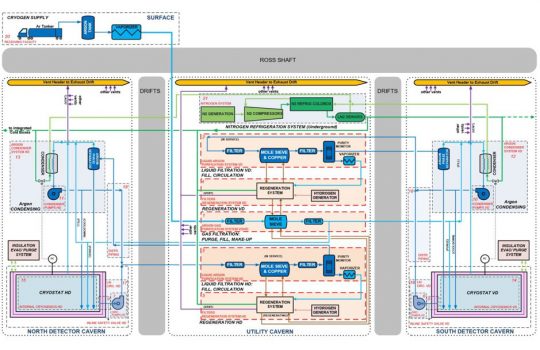

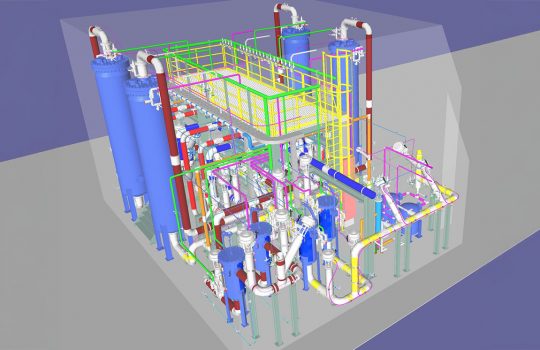

Maggie II is just one part of LBNF/DUNE. The entire project is a colossal scientific undertaking that includes a chain of particle accelerators and detectors at Fermilab that will project a beam of neutrinos 800 miles though the curvature of the Earth to a set of five-story-high particle detectors located a mile underground inside massive caverns at SURF.

A team from Fermilab and SURF recently completed a successful test lift, which involved moving one of the six-ton, L-shaped steel beams needed for the underground construction of the DUNE detectors.

Once the beams are lowered 4,850 feet underground, Maggie II will again be used to move the beams out of the elevator cage and into the caverns, where they will be assembled into a structure to support the massive cryogenic vessels for the Long Baseline Neutrino Facility.

International partnership

A team of engineers and technicians from around the world who are involved in the construction of LBNF/DUNE worked together to build the hovercraft.

“This didn’t come from one person,” said Pingulkar. “We had people from CERN, from SURF, from Fermilab — everyone contributed in some way to the design. It was very collaborative.”

Similar air pressure technology is employed at CERN to move the massive CMS particle detector. During a recent planned shutdown of CMS, each of its 15 circular slices, nearly 50 feet tall, was moved back and forth using pressurized discs to allow technicians to reach inner components which are normally hidden.

The DUNE collaboration extends far beyond the development of Maggie II. In total, DUNE comprises more than 1,400 scientists and engineers from over 200 institutions in 36 countries, plus CERN. The steel is an in-kind contribution from CERN and is the first time the European science organization has provided infrastructure for a project on American soil.

In 2024, crews completed excavation for LBNF/DUNE’s massive caverns. Work is currently underway to outfit the caverns with conventional infrastructure, such as electricity, water, HVAC and fire suppression equipment. Beginning in late 2025 and early 2026, Maggie II will begin moving the massive steel beams underground for construction of the detector support structures.

Fermi National Accelerator Laboratory is America’s premier national laboratory for particle physics and accelerator research. Fermi Forward Discovery Group manages Fermilab for the U.S. Department of Energy Office of Science. Visit Fermilab’s website at www.fnal.gov and follow us on social media.

Sanford Underground Research Facility is operated by the South Dakota Science and Technology Authority (SDSTA) with funding from the Department of Energy’s Office of Science. We are America’s Underground Lab. Our mission is to advance world-class science and inspire learning across generations. Visit SURF at www.sanfordlab.org.