Preparations for the construction of the first detector module of the Deep Underground Neutrino Experiment are rapidly progressing. Members of the international DUNE collaboration have begun the final tests of detector components that will be shipped to South Dakota. There they will become part of a one-of-a-kind experiment designed to study some of the most elusive particles in the universe: neutrinos.

DUNE is an experiment aimed at exploring the nature of neutrinos. Scientists hope that unlocking the secrets of these particles will shed light on some of the biggest mysteries in physics, such as why the universe is made of matter and how neutron stars and black holes are forged in the aftermath of exploding stars.

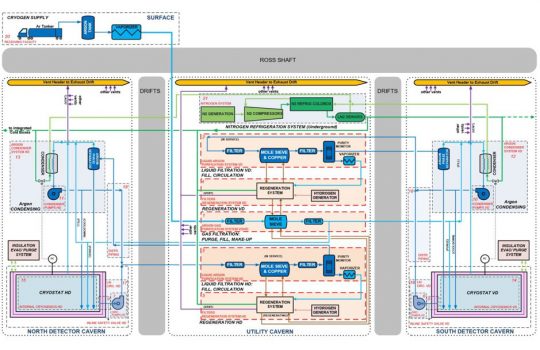

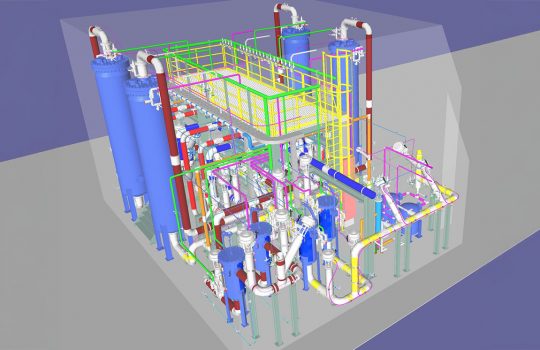

DUNE, hosted by the U.S. Department of Energy’s Fermi National Accelerator Laboratory, will be housed at two locations: the Fermilab site in Illinois and the Sanford Underground Research Facility in South Dakota. The far detector, an enormous structure envisioned to ultimately comprise four modules, will be located 1.5 kilometers underground at SURF. Each module will be a liquid-argon time projection chamber, or LArTPC, designed to be filled with 17,000 tons of argon, an element commonly found in air that is ideal for studying neutrinos.

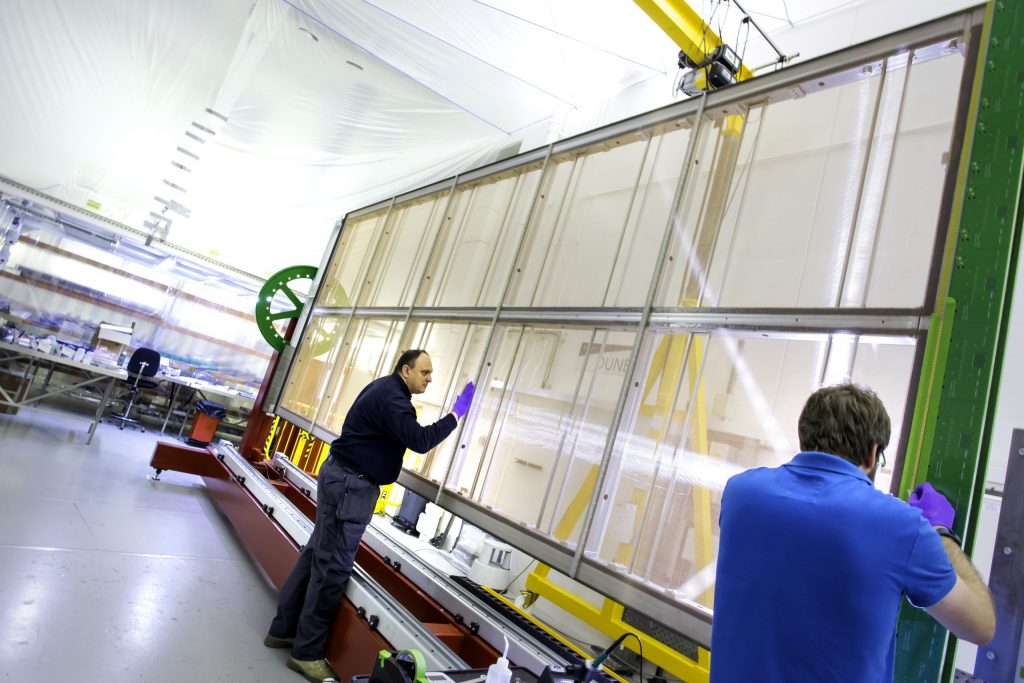

The construction of wire planes, called anode plane assemblies, is underway at Daresbury Laboratory in the U.K. The laboratory will ship 136 APAs to South Dakota for the Deep Underground Neutrino Experiment. Photo: DUNE collaboration

The first DUNE detector module to be built at SURF will employ horizontal drift technology. When neutrinos collide with the argon atoms inside the module, they will produce charged particles. These charged particles knock out electrons as they travel through the argon. The electrons are attracted by a strong electric field towards anode plane assemblies, or APAs, which record a projection of where the electrons were produced. By measuring the timing of when electrons hit the APAs, scientists are able to reconstruct three-dimensional particle tracks.

When complete, the first detector module will contain 150 APAs, each a large rectangular plane approximately 2.3 meters by 6 meters in size and composed of tightly wound copper-beryllium wires. “We are going to effectively plaster a wall with a grid of wires,” said Justin Evans, a professor of physics at the University of Manchester. He is leading the effort to build APAs in the U.K.

The technology for the first module was successfully tested in a scaled-down version called ProtoDUNE at the CERN Neutrino Platform in 2019. Although it was only one-twentieth of the size to the final DUNE detector module, it still was the largest LArTPC ever constructed and operated.

“That was the first time that we in the U.K. built any of these wire grids and took data from them,” said Evans. “And they worked wonderfully.”

In addition to proving that the detector technology would work, the horizontal drift prototype revealed where design improvements could be made. With this in mind, scientists designed ProtoDUNE II, an upgraded prototype that will undergo tests at CERN this year.

“With a prototype, there’s always lessons learned,” said Thomas Wieber, the installation team leader at CERN. “We want to prove that what we think is going to work better actually does work better.”

DUNE scientists are also working on developing the technology for a vertical drift detector, which is the planned technology for the second far detector module. Preparations for testing the new technology in a separate prototype detector, known as vertical drift module-0, are underway at CERN as well.

Testing the full assembly process

Testing all aspects of the horizontal drift module assembly also involves ensuring that all the detector components, which come from DUNE collaborators around the world, will arrive safely. To ensure this process goes smoothly, ProtoDUNE II also has served as a testbed for the installation process. The groups involved in manufacturing the detector components brought all their test parts together at CERN to assemble and test the prototype.

“We have had collaborators coming in from all over the world,” said Daniela Macina, the installation coordinator for the horizontal drift detector at CERN. “This is the first time we’ve integrated and installed the final DUNE horizontal drift detectors all together.”

ProtoDUNE II contains four APAs. All four were tested in a cold box filled with super-cold gaseous nitrogen in order to ensure that the electronics function properly at frigid temperatures. All four APAs passed the test. They then were assembled in the ProtoDUNE II cryostat, along with other parts of the prototype. These parts include the electronics and light sensors, which identify photons that are released when neutrinos interact with the liquid argon in the detector.

The DUNE collaboration has finished the assembly of their large horizontal drift prototype detector, known as ProtoDUNE II, at CERN. It is the final test before ramping up mass production of DUNE detector components. Photo: DUNE collaboration

“We needed to assemble things according to a procedure that will be as close as possible to the one we’ll use in South Dakota,” Macina said.

Later this year, the team will fill ProtoDUNE II with liquid argon and shoot a beam of particles through the detector to test it. “We don’t expect big surprises, because there were only minor changes between ProtoDUNE and ProtoDUNE II,” said Macina.

As the final work on ProtoDUNE II takes place at CERN, scientists are also ramping up production of the APAs that will be installed at SURF. Of the 150 APAs that will be installed in the first module of the far detector, 136 APAs will be produced at the Daresbury Laboratory in the U.K., and another 14 will be produced at the University of Chicago.

To support the mass production of these parts, the Daresbury Laboratory in the U.K. has constructed an APA factory where the team has set up four production lines, each with six-meter-long machines for winding the wires around steel frames to create the APAs.

“We have four of those set up, all working in parallel,” Evans said. “We’re trying to get to the point where each production line can produce one APA every two months.”

Shipping detector components to South Dakota

Activities related to the detector installation have also started up in South Dakota, where the excavation of the caverns for the DUNE far detector are about 60% complete. In early November, the team shipped one of the APAs from the first prototype at CERN to SURF for a logistics test. The process of transporting the long, rectangular APA from Europe to the United States, offloading the structure, then lowering it a mile below the ground through a relatively narrow mineshaft was successfully completed.

“We’re using older APAs to validate those procedures so that we’re not going to damage anything when we start bringing the real APAs to SURF,” said Fermilab scientist Eric James, a technical coordinator who focuses on DUNE’s horizontal drift detector.

Despite all the details that need to be worked out to bring the first DUNE detector module to life, DUNE scientists are not losing sight of their ultimate goal: exploring a new frontier of neutrino science.

“I’m hugely excited about what we will see when we switch this thing on,” Evans said. “There is so much the neutrino can tell us about the universe.”

Fermi National Accelerator Laboratory is supported by the Office of Science of the U.S. Department of Energy. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, please visit science.energy.gov.