In recent months, the neutrino research facility at the European laboratory CERN has been bustling with activity. Scientists, engineers and technicians from around the world have gathered there to assemble a large prototype of a new particle detector to study the neutrino, one of the most mysterious types of particles in the universe.

Neutrinos are everywhere, but they rarely interact with matter. Each second, trillions of these particles traverse our bodies and leave without a trace. By studying these ghost-like particles, physicists hope to answer questions, such as: Why is the universe made of matter? What is the relationship between the four forces of nature? How are black holes formed in the aftermath of an exploding star?

Researchers working on the international Deep Underground Neutrino Experiment, hosted by the U.S. Department of Energy’s Fermi National Accelerator Laboratory, hope to solve these mysteries. Their work on the prototype detector at CERN brings them a step closer to achieving this goal.

A crane lowers a charge readout plane attached to the top of the cryogenic vessel onto the vessel. Photo: DUNE collaboration

The infrastructure needed for DUNE is expansive. It includes a new particle accelerator at Fermilab, which will produce a neutrino beam that will pass through 1,300 kilometers of earth before reaching the Sanford Underground Research Facility in South Dakota. At SURF, these particles will be greeted by the DUNE far detector, a gigantic subterranean detector housed 1.5 kilometers below the surface. The detector will comprise huge detector modules containing argon, an element whose highly stable nature makes it perfect for studying neutrinos. Excavation of the underground caverns for the DUNE far detector is about 60% complete.

Testing new technology

Members of the DUNE collaboration, which includes scientists and engineers from more than 35 countries, are busy at work designing, testing and building the components of the first two DUNE detector modules to be installed at SURF. Module one will be a horizontal drift detector, which is based on a tried-and-tested technique that will be scaled up for DUNE. The mass production of components for this first module already has begun. The second module, known as the vertical drift detector, will feature new technology. Testing has been ongoing for the last two years.

“I expect exciting physics out of both the horizontal and vertical drift detectors,” said Steve Kettell, the technical coordinator for the vertical drift detector, based at the DOE’s Brookhaven National Laboratory. “But the vertical drift technology opens up significant opportunities for building additional detectors that are lower in cost and easier to install.”

Horizontal vs. vertical

On a basic level, horizontal and vertical drift detectors work in the same way. When a neutrino interacts with an argon atom inside the detector’s liquid-argon-filled chamber, the particles produced in this interaction release electrons. A strong electric field between opposite sides of the detector chamber pushes these loose electrons to an anode, a large structure that detects the arrival of charged particles. In a horizontal drift detector, the electric field exists between two opposing walls, and the electrons drift horizontally; in a vertical drift detector, the electric field runs between the bottom and top of the detector, and the electrons drift vertically. The argon-neutrino interaction also produces a brief flash of light that both detectors capture with a separate photon detection system.

“Fundamentally, there’s nothing different about vertical drift and horizontal drift,” Kettell explained. “We are detecting neutrino events in essentially the same manner.”

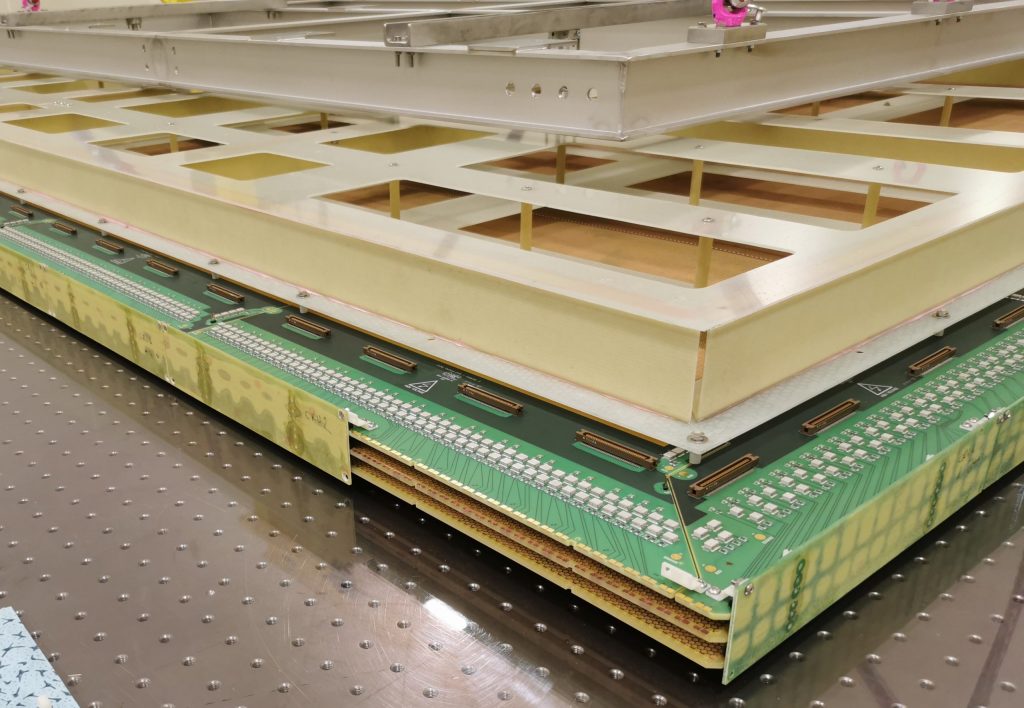

The differences are in the details. The anode of the horizontal drift detector consists of large planes of tightly wound wires, known as anode plane assemblies, or APAs. They are 6 meters tall and 2.3 meters wide. The anode of the vertical drift detector, on the other hand, will be composed of charge readout planes, or CRPs. They are large, perforated-printed circuit boards that are 3 meters by 3.5 meters in size and have copper strips printed onto their surfaces. Like the wires in the APAs, the copper strips in the CRPs will collect the drifting electrons.

A close-up of the charge readout planes for the DUNE vertical drift detector. Photo: DUNE collaboration

The DUNE vertical drift detector will feature multilayer CRPs at the top and at the bottom. “The CRPs have perforated 2.5-millimeter holes, so that electric charge can pass through and go to another layer to get collected,” said Dominique Duchesneau, leader of the CRP consortium and a physicist at the French National Centre for Scientific Research. Each CRP layer has differently orientated copper strips, he added, which “gives you the possibility to have multiple views of the electrons.”

A key advantage of CRPs is that because they are made of simple metal-plated circuit boards rather than a tight coil of wires, they are cheaper and easier to manufacture and install than APAs.

“With the vertical drift detector, we’re trying to demonstrate that we can build a less expensive detector that works equally well,” Kettell said.

Because the vertical drift detector technology requires fewer elements than the horizontal drift, it provides a larger active volume. A larger active volume means that there will be more space in which particle interactions can be collected, said Inés Gil-Botella, a DUNE physics coordinator based at the Centre for Energy, Environmental and Technological Research in Spain. “You’re maximizing the possibility of seeing neutrino interactions in this liquid argon.”

Another innovation is the photon detection system DUNE scientists plan to build for the vertical drift detector, an upgrade of the ARAPUCA technology developed for the first DUNE far detector module. This new system will cover all four cryostat walls as well as the cathode with photon detection modules. (In contrast, in the horizontal drift detector, the photon detectors only are embedded in the APA planes, behind the wires.) To power and read out the photo sensors on the high-voltage cathode, which is set to 300 kilovolts, the vertical drift team uses a powerful laser that provides power via optical fibers.

In addition, the argon within the vertical drift detector will be doped with xenon to enhance the number of photons that get detected when particles interact with atoms in the liquid —and to enhance the uniformity of light detection throughout the chamber. Together, these features will make this photon detection system more capable of detecting low-energy physics events, such as those triggered by supernovae or solar neutrino events, Gil-Botella said.

A bustle of activity

This newly designed high-voltage extender helps create a 300,000-volt electric field between the top and bottom of the vertical drift prototype detector. Photo: DUNE collaboration

The team working on the DUNE vertical drift detector comes from around the world. Major contributions are being made by CERN, France, Italy, Spain and the U.S. But members also come from several other countries in Europe, Asia and Latin America. “There’s been tremendous progress on many fronts,” said Kettell.

This group has been busy. To date, they have successfully tested small-scale, 32-centimeter-by-32-centimeter CRPs in a 50-liter liquid-argon-filled chamber fitted with a cathode, electronics and a photon detection system. This early prototype was able to collect data from cosmic-ray tracks with “good signal-to-noise performance,” said Kettell. They have also tested full-size, 3-meter by 3.5-meter CRPs with the cathode, electronics, and the photon detection system in a large coldbox at CERN.

The team has demonstrated that the components of the vertical drift detector could read out signals at 300 kilovolts — the high voltage that will be needed for creating the electric field in the full-sized DUNE detector. They have also shown that electrons can drift six meters — the maximum distance electrons will travel in the final-size module — and use the CRPs to receive these tracks. “The next big milestone we’ll face is the installation of all of the systems together at a larger scale,” Gil-Botella said.

The team is now assembling parts into a larger vertical drift prototype, dubbed “vertical drift module-0,” in a large cryogenic vessel at CERN, about the size of a small house. This prototype will contain two full-sized CRPs on both the top and bottom of the detector, with the cathode installed in the middle, as well as an advanced photon detection system. Electrons knocked loose in the upper half of the detector will drift upward toward the CRP set at the top, and electrons produced in the lower half will drift in the down direction, until they reach the CRP layers at the bottom. CRP development has been led by France and CERN, with the construction of the top CRPs at CERN and the bottom CRPs in the U.S.

The DUNE researchers aim to complete the installation of the vertical drift prototype detector in spring 2023. Once all systems have been tested, the team will fill the detector with liquid argon and turn it on, so that scientists can observe the tracks left by particle beams and cosmic rays that pass through it.

Ultimately, the goal is to have the components of the vertical drift detector ready to be installed in one of the large caverns in South Dakota in 2027.

“What I really would like to see is the installation of the first CRPs in the big cryostat at SURF, which will come in several years,” Duchesneau said. “In the meantime, I think module-0 running and taking data in the real configuration of the vertical drift is a very exciting step.”

Fermi National Accelerator Laboratory is supported by the Office of Science of the U.S. Department of Energy. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, please visit science.energy.gov.