Cary Kendziora had expected the long, slender temperature profile monitor to droop a bit, but not as much as this. As part of a joint project with the University of Hawaii at Manoa, Kendziora, a mechanical engineer at the U.S. Department of Energy’s Fermilab, had designed the device to measure the variation in temperature inside a massive neutrino detector located at the European laboratory CERN. The detector, the size of a small house, is filled with liquid argon. The temperature profile monitor is a solid piece of metal about 8 meters tall — about two stories tall — and as thin as a curtain rod. It bowed considerably when it was horizontal.

Kendziora said he’d never worked with such a long, solid piece of metal that was also so narrow.

“It turned out to be a lot more flexible than I imagined because of its length,” Kendziora said. “That was a surprise.”

As a workaround, he helped build an exoskeleton support to keep the device rigid while it was being installed.

The detector, one of two known as the ProtoDUNE detectors, contains 770 tons of liquid argon maintained at temperatures around 90 Kelvin. That’s a chilling minus 300 degrees Fahrenheit. As particles pass through the detector, they occasionally smash into the nuclei of argon atoms. The particles emerging from these collisions release electrons from argon atoms as they pass by. These electrons drift toward sensors that record their tracks. The tracks, in turn, give scientists information about the particle that started the reaction.

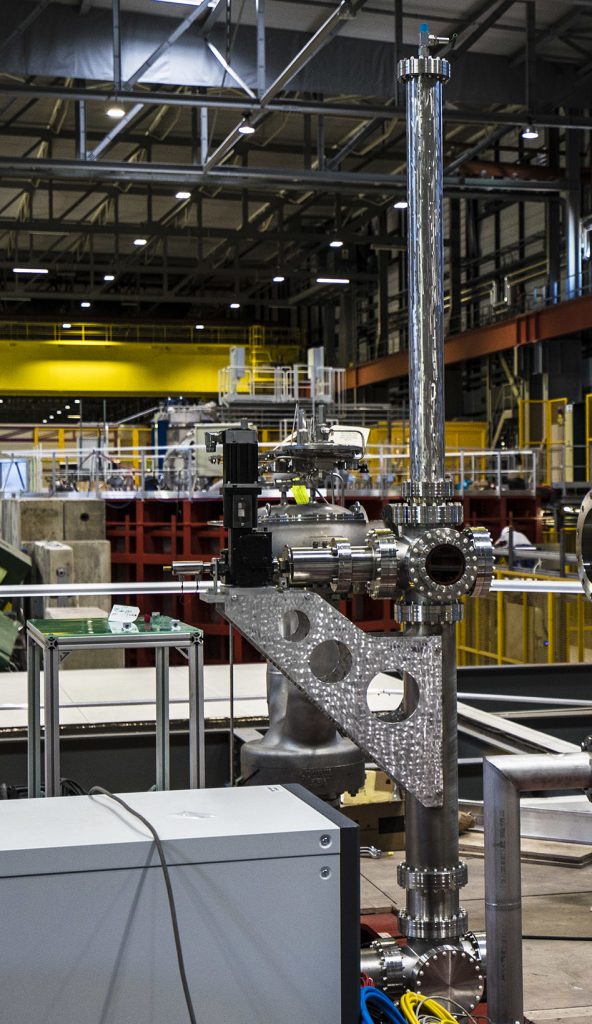

The temperature profiler from one of the ProtoDUNE detectors stands 8 meters tall. Photo: Cary Kendziora

The ProtoDUNE detectors are prototypes for the international, Fermilab-hosted Deep Underground Neutrino Experiment. The DUNE detector, expected to be complete in the mid-2020s, will be mammoth, comprising four modules that are each nearly as long as a football field.

In liquid-argon detectors like DUNE and the ProtoDUNE detector, monitoring the variation in internal temperature is important because it’s correlated to the argon’s purity. ProtoDUNE contains 770 tons of liquid argon. DUNE will hold 70,000 tons. At this scale, the purification efficiency has to be checked regularly. If the argon doesn’t mix properly, it begins to stratify into layers of different temperatures, which can affect how far electrons can drift.

“If the argon is pure, the electrons can drift the distance to the ProtoDUNE sensors, no problem,” said Jelena Maricic, an associate professor of physics at the University of Hawaii at Manoa who leads the group that worked on the design, construction and installation of the ProtoDUNE dynamic temperature profile monitor, along with Kendziora.

But impurities have a great affinity for electrons and can trap them on their way to the sensors. And if they’re trapped, they won’t be detected, or at least not as easily.

The temperature profile monitor hangs vertically from the detector’s ceiling near one corner of the detector, taking readings of the circulating liquid argon. By monitoring the argon’s temperature, scientists will be able to tell right away whether any problems are developing in the detector.

Jelena Maricic (second from left) and Cary Kendziora (far right) prepare to install the temperature profile monitor in a ProtoDUNE detector. Photo: Olexiy Dvornikov

Calibration by cross-reference

Designing and building a temperature profile monitor that is accurate to within tens of millikelvin inside a massive liquid-argon detector is no small feat. While the degree of bowing was an unexpected problem, it was hardly the most difficult challenge to overcome. Kendziora ticked off a laundry list of them.

“It had to be electrically and thermally isolated, and leak-tight,” he said. “And it’s a high-purity application, so all the materials had to be selected based on their not contributing any contaminants to the liquid. All the little threaded holes that the components are screwed into had to be vented so they wouldn’t trap any gas that would give off oxygen over a long period of time. All the parts had to be cleaned.”

The entire design of the profile monitor also needed to address a unique question: How do you calibrate a probe that is sealed inside a giant box full of liquid argon? Erik Voirin, an engineer at Fermilab, and Yujing Sun, a postdoc in Maricic’s lab, independently hit upon the same, elegant idea.

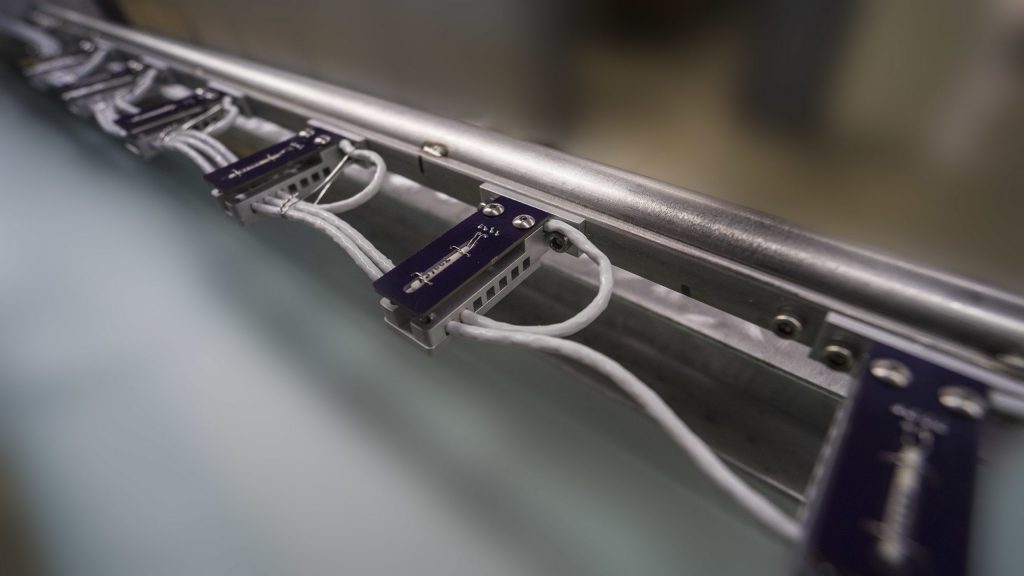

The team designed the profile monitor with an array of 23 motor-driven, remotely moveable sensors along its 8-meter height. Each takes a reading of the argon immediately surrounding it. And since they’re moveable, not only can a sensor take the temperature in multiple locations, but a single location’s temperature can be read out by more than one sensor.

The profile monitor is outfitted with an array of 23 motor-driven, remotely moveable sensors along its 8-meter height. Each takes a reading of the argon immediately surrounding it. Photo: Cary Kendziora

Voirin, a thermal-fluids engineer, performed the computational fluid dynamics simulations for ProtoDUNE. Sun tested and demonstrated the idea to work with the prototype using just four sensors in 2017, deploying the rod in the 35-ton liquid-argon detector.

“Our system allows you to move the sensors along the vertical axis and perform cross-calibration,” Maricic said.

One could use sensor A to take the temperature at, say, the 3-meter mark, and then check its reading against sensor B’s at the same location. That way, scientists can determine if any sensor is out of whack.

Maricic said that the University of Hawaii group team, will be performing the cross-calibration in the late November or early December.

The DUNE far detector will require a similar temperature profile monitor that adheres to the same set of strict requirements that the ProtoDUNE detector needed – but with one difference. DUNE is much larger than ProtoDUNE, so its profile monitor needs to be scaled up accordingly. It will be 15 meters long — nearly double the length of the prototype profile monitor.

“I don’t have a solution for the long length,” Kendziora says, other than to construct another extensive support infrastructure.

Another engineering effort for DUNE— and he’s on top of it.