Your average screen door isn’t exactly a marvel of modern technology. However, devices that resemble colossal screen doors — 150 of them, in fact — will play a crucial role in unraveling one of the universe’s greatest mysteries. These are called Anode Plane Assemblies, or APAs, and they are key components of the Deep Underground Neutrino Experiment, an ambitious international project aiming to untangle the mysteries surrounding matter–antimatter asymmetry, without which the universe as we know it would not exist.

Ever since the doors of modern physics were cracked open over a hundred years ago, scientists have been building increasingly ingenious devices to develop an understanding of the building blocks of matter and the forces that govern them. To this end, the U.S. Department of Energy’s Fermi National Accelerator Laboratory is hosting an international collaboration of institutions, scientists and engineers to construct DUNE in the United States.

Particle detectors are intricate, sophisticated devices for learning about the origins of the universe and the matter and energy that it is made of. The DUNE collaboration is set to build enormous detectors a mile underground at the Sanford Underground Research Facility in Lead, South Dakota. Their mission? To study neutrinos — electrically neutral subatomic particles so weakly interacting that they pass through matter almost undisturbed. An additional smaller detector will be installed 800 miles away on the grounds of Fermilab in Batavia, Illinois, just downstream from an upgraded particle accelerator complex at the laboratory that will generate the highest-intensity beam of neutrinos on the planet.

“We want to study a quantum phenomenon called neutrino oscillations,” said Pip Hamilton of Imperial College in the U.K. “Neutrinos spontaneously flip from one type to another as they travel through space and time, so we need detectors at each end of their journey to count how many of each type we see at the beginning versus at the end. Since the beam spreads, the detector at the far end has to be very large to capture a meaningful number of neutrinos.”

Since the beam spreads, the detector at the far end has to be very large to capture a meaningful number of neutrinos.

Pip Hamilton, Imperial College

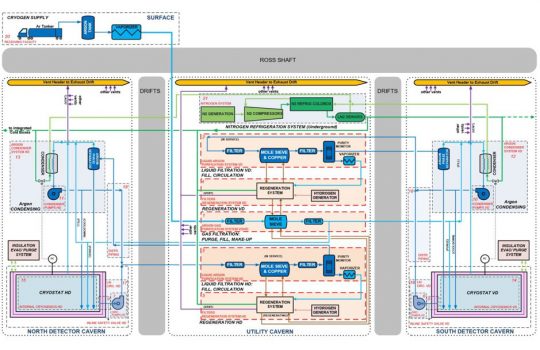

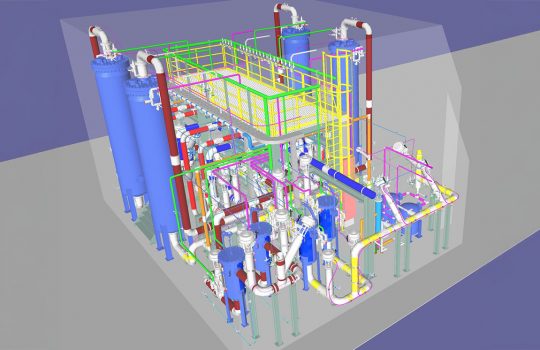

The DUNE far detectors in South Dakota will be housed in cryostats (think gargantuan thermos bottles) standing roughly 58 feet tall, 62 feet wide, and 215 feet long. The cryostats will be filled with liquid argon, a heavy, transparent fluid that must be kept at a cryogenic temperature of minus 303 degrees Fahrenheit (minus 186 degrees Celsius).

Neutrinos can’t be measured directly, but when one hits an argon nucleus, the interaction releases energy that ionizes electrons in the argon. A strong electric field, created between a cathode and an anode in the detector, drives the negatively charged electrons toward the positively charged anode, which registers the signals and sends them to the readout electronics as data.

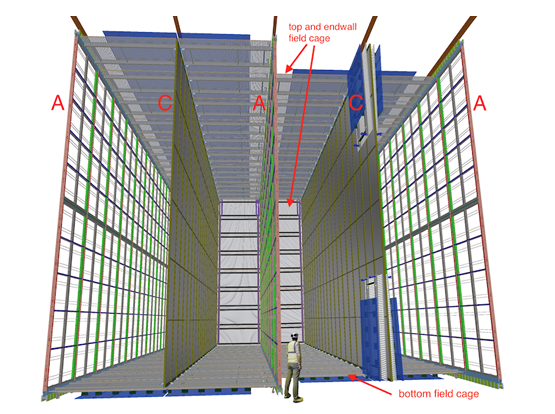

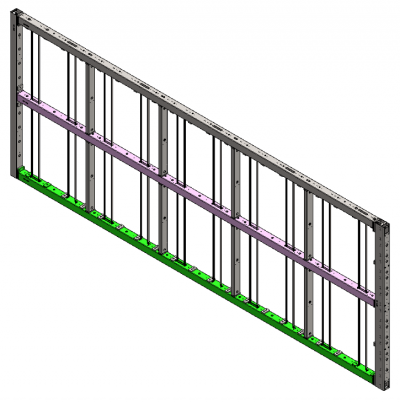

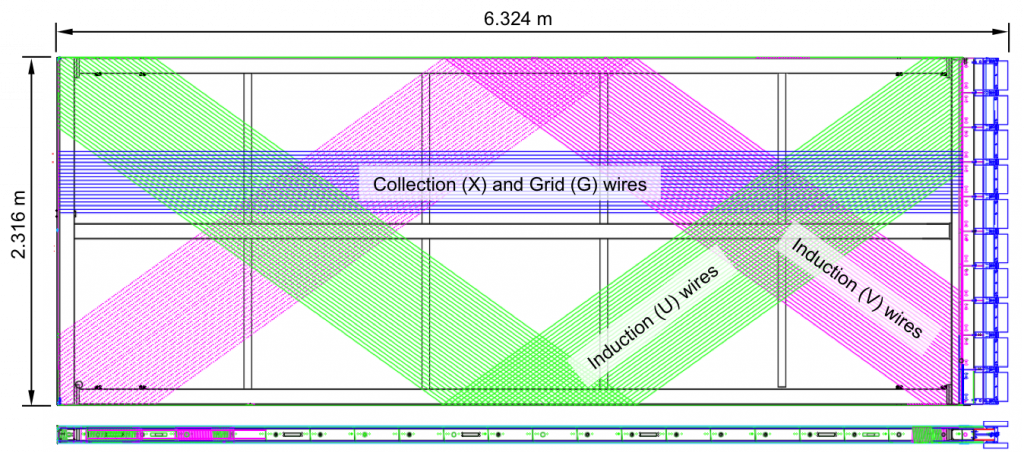

The DUNE detector called FD-HD, which stands for Far Detector-Horizontal Drift, features sets of parallel vertical anodes and cathodes that create horizontal electric fields. (see figure 1) The anodes are composed of the DUNE collaboration’s Anode Plane Assemblies. An APA’s rectangular stainless steel frame, measuring 20 feet by 7 1/2 feet, is instrumented with several layers of copper-beryllium sensing wires strung at varying angles and biased at slightly different voltages, all relatively close to ground (zero volts). This screen-door-like assembly allows the scientists to construct a 3D picture of neutrino interactions regardless of the directions the electrons travel.

The APAs will be stacked in two tiers and arranged in three rows, 25 stacks wide, to form three anode planes spanning the full height and length of the cryostat. Cathode planes, set at minus 180,000 volts, will be placed between each pair, creating four adjacent electric field volumes, each 11 ½ feet wide.

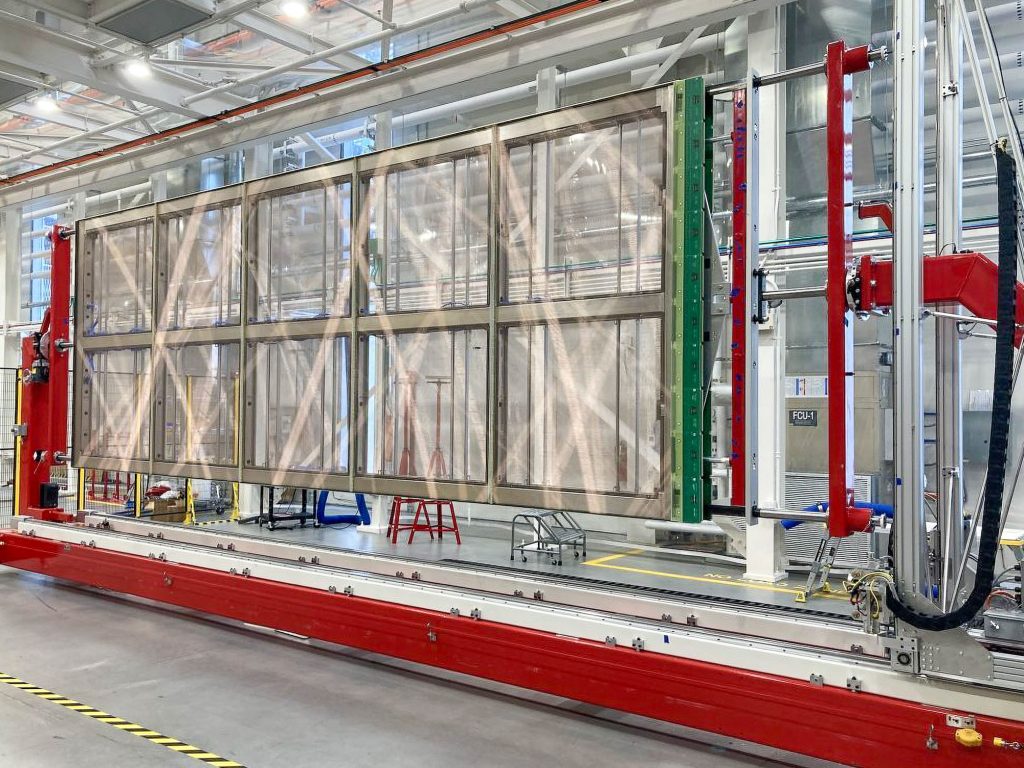

The high-precision measurements that DUNE aims for require high-precision detector components — fractions of millimeters make a difference. Furthermore, the components can’t contain materials that will contaminate the argon, and the components must be kept very clean for the same reason. The bare APA frames, custom made by commercial industry, are shipped to DUNE’s two APA production points — one at the Science and Technology Facilities Council’s Daresbury Laboratory in the U.K. and the other at the University of Chicago in the U.S. — where they are checked for alignment, carefully cleaned, and meticulously outfitted with the hardware and wires that turn them into APAs.

Because neutrino interactions with liquid argon release both charge and light, DUNE’s detectors greatly benefit from an additional system for light detection. Liquid argon is transparent and an excellent scintillator, emitting light that helps precisely time each detected particle interaction. Detecting this light requires a different technology from charge detection, which means an additional component is needed. In the FD-HD design, 10 sets of light detectors are placed within an APA frame, positioned beneath the wire layers. (see figure 2)

The light detectors will be installed once the APAs are underground and being prepared for installation into the cryostat. However, the hardware and cabling they require must be installed beforehand, prior to winding the wire layers. All this labor is done by hand in a clean room and requires hundreds of screws, bolts, washers, nuts and ties to affix various plates, rails, spacers, sensors, cables and electronics boards to the frame.

“The placement and orientation of each element, the order in which it is installed, and the size and torque of the screws that hold it in place have all been explicitly engineered, and the instructions must be followed to a T,” said Daniel Salisbury, the lead detector technician at Daresbury. “An added complication is the fact that whereas the bare frames are all identical, the detector requires multiple variants in terms of the outfitting.”

Finding a way to wire the APAs efficiently took great ingenuity. Each APA requires a total of 3,520 individual wires, strung in four layers. At 0.15 millimeters, this wire is only slightly thicker than an average human hair, is strung slightly under a half centimeter away from all its neighbors and is uniformly tensioned to within about 10% of 1 1/2 pounds. The outer and inner layers run lengthwise along the frame, and the two in-between layers wrap around the frame in a helical fashion. (see figure 3) Their positions, critical for the high-precision measurements that DUNE intends to make, cannot deviate more than a half millimeter at any point.

No off-the-shelf machine was available for this unique winding job, and stringing the wire manually for 150 APAs was out of the question. While some detector components can be outsourced to industry for construction, most must be designed, manufactured and assembled by the experiment’s collaborators. DUNE charged a team at Physical Sciences Laboratory of the University of Wisconsin at Madison with designing a computer-controlled machine that would allow the large, heavy APA frame to remain stationary while a spool of wire passes across the plane of the frame and around its edges many times, in the right direction, adjusting its position on each turn based on intricately constructed algorithms.

“The machine has a device called a winding head that allows wire to unwind from a spool at a carefully regulated tension,” said Benjamin Oye, a research engineer at the Chicago site. “The principal innovation of this machine is that it transfers the head back and forth between the two sides, passing over, around, and under the frame, via an extendable arm.”

A given layer of wire is wound as one continuous strand and on each pass around the frame, the wire is laid against designated soldering points on both sides. Within the head, the wire from the spool passes through pulleys that move a plunger attached to a spring. The load on the spring indicates the wire tension, which is continuously measured, allowing dynamic control of the tension.

“As the frame cools in the liquid argon, or returns to room temperature after a cold test, the contraction or expansion of the frame could cause wires either to sag, or to stretch and snap,” said Oye. “So, maintaining the proper tension is very important.”

Before winding each layer, the team manually attaches electronics boards as well as spacers to set the wire positions for that layer, and spacers to separate the layers from each other. When a layer is completely wound, the wire is soldered by hand at each connection point on the board, then snipped. Finally, protective shields are placed on the completed APA to protect it from both damage and dirt, before packaging and shipping.

The fastest that an APA has been constructed starting from the bare frame is 30 days, but 40 days is more typical. With five — soon to be seven — winding machines, a larger team, and an earlier start, the Daresbury factory produces on average three APAs per month. The Chicago factory, which got up and running in 2024 with a single winder, produces roughly two every three months.

This production rate ensures that by the time far detector installation begins in South Dakota in early 2028, the necessary number of APAs will arrive each month, until all 150 of DUNE’s sophisticated “screen doors” are safely delivered to take their place in one of the most ambitious physics experiments ever conceived.

Fermi National Accelerator Laboratory is America’s premier national laboratory for particle physics and accelerator research. Fermi Forward Discovery Group manages Fermilab for the U.S. Department of Energy Office of Science. Visit Fermilab’s website at www.fnal.gov and follow us on social media.